Selecting a basic PDU with the right capacity and features improves business continuity and operational reliability. Companies that choose wisely benefit from reduced downtime, scalable growth, and efficient maintenance. Evaluate power needs, outlet types, and safety features to ensure dependable performance and long-term value.

Key Takeaways

- Assess your business’s total power needs carefully and choose a PDU with enough capacity to avoid overloads and downtime.

- Select PDUs with the right outlet types, mounting options, and voltage compatibility to fit your equipment and rack setup.

- Prioritize safety features like circuit breakers and surge protection to protect your devices and ensure continuous operation.

PDU Basics and Business Importance

What is a PDU?

A Power Distribution Unit, or PDU, serves as a central device for distributing electrical power within business IT environments. Companies rely on PDUs to allocate power efficiently to servers, networking equipment, and storage systems. These units act as a bridge between the main power source—such as a wall outlet, generator, or uninterruptible power supply—and the devices that require electricity.

PDUs simplify cabling, reduce clutter, and ensure each device receives the correct amount of power. They also help prevent overloads and support maintenance without causing downtime.

Common types of PDUs include basic, metered, monitored, and switched models. Each type offers unique advantages. For example, basic PDUs provide simple, cost-effective power distribution, while monitored and switched PDUs enable remote management and advanced monitoring.

| PDU Type | Description | Advantages |

|---|---|---|

| Basic PDU | Simple power strip with multiple outlets; no data collection or remote access. | Easy power distribution to multiple devices; low cost. |

| Metered PDU | Built-in current meter providing local real-time load monitoring; no network connectivity. | Immediate load awareness; can be upgraded with smart power cables for remote monitoring. |

| Monitored PDU | Networked device allowing remote monitoring of voltage, power, frequency, and load in real-time. | Enables historical data review, trend analysis, alarm notifications; supports wired or wireless networking. |

| Switched PDU | Includes all monitored PDU features plus remote on/off control of individual outlets. | Enhances power management, reduces human error, increases safety, allows scheduling and load balancing. |

Why the Right PDU Matters for Business Reliability

Selecting the right PDU directly impacts the reliability of business-critical equipment. Companies that use dual input PDUs benefit from automatic switching between independent power sources, which ensures continuous power delivery and prevents downtime. Automatic transfer switching protects sensitive equipment by enabling seamless failover during power interruptions.

Businesses that integrate PDUs with backup systems, such as UPS units and generators, maintain operations even during extended outages. Features like load balancing, advanced monitoring, and remote management support proactive maintenance and extend equipment life. Regular testing and proper configuration further reduce the risk of misconfiguration and ensure the system responds correctly during power events.

Remote monitoring allows real-time tracking of power usage and environmental conditions, enabling early detection of issues and reducing downtime.

By choosing the right PDU, organizations can achieve over 99% uptime in critical environments and significantly reduce the risk of power-related failures.

Key PDU Selection Factors

Assessing Power Capacity and Requirements

Businesses must accurately determine their total power requirements before selecting a PDU. This process begins with understanding the load on each phase and applying safety de-rating factors, such as limiting continuous load to 80% of the PDU’s rated capacity. For three-phase PDUs, the total power calculation uses the formula:

Total Power = (Total Three Phase Current) × (208V) × √3

For single-phase PDUs, the formula is:

Total Power = (Total Current) × (208V)

Internal circuit breakers set the maximum input current, so their ratings must be considered. Companies often use specialized capacity planning tools to input expected amperage per outlet, ensuring the calculated load does not exceed the PDU’s capacity. These tools highlight overloads and errors, allowing businesses to plan for redundancy and avoid operational risks.

Exceeding a PDU’s rated power capacity can lead to tripped breakers, equipment downtime, and even damage to connected devices. Proper sizing and planning help maintain safe operation and business continuity.

To further enhance accuracy, organizations deploy branch circuit monitors and intelligent PDUs that provide real-time data on power consumption. This approach ensures that the infrastructure remains within safe operating limits and supports future growth.

Choosing the Right Number and Type of Outlets

Selecting the correct number and type of outlets is essential for supporting all connected devices and accommodating future expansion. Businesses should first determine whether they require AC or DC power, as this affects connector types and circuit design. The PDU must offer enough outlets for current equipment, with additional capacity for growth. Devices with redundant power supplies may need PDUs capable of controlling multiple power inputs simultaneously.

- Consider the physical size and layout of the PDU to ensure it fits within the available rack or cabinet space.

- Evaluate the power handling capacity and ensure it matches the requirements of all connected devices.

- Identify the types of connectors needed, such as NEMA, IEC C13, or C19, to ensure compatibility with business equipment.

- Plan for outlet grouping features to manage redundant power supplies efficiently.

Different PDU types accommodate a range of business equipment. Basic PDUs provide simple distribution, while metered and smart PDUs offer monitoring and remote management. Outlet types like NEMA, IEC, and universal connectors ensure compatibility with diverse devices, supporting both standard IT equipment and higher power servers.

PDU Mounting Options for Your Setup

Mounting options play a significant role in optimizing space, airflow, and accessibility within server racks and network cabinets. The most common mounting styles include vertical and horizontal configurations. Vertical PDUs maximize outlet count without consuming valuable rack space, making them ideal for high-density environments. Horizontal PDUs suit low-power racks or setups with limited rear space.

- Vertical power strips mount inside cabinets using clips and come in various heights.

- Horizontal rack-mount power strips are available in multiple amperage configurations.

- Custom designs can address unique rack requirements.

- Remote access power strips provide additional control and monitoring.

Mounting PDUs on either side of the rear cabinet, often combined with cable management panels, helps maintain organized cabling and efficient airflow. The choice of mounting option also affects cooling and maintenance. For example, open-frame racks improve airflow and accessibility, while enclosed racks offer security but may restrict cooling.

| Mounting Option | Impact on Airflow | Impact on Accessibility | Additional Notes |

|---|---|---|---|

| Open-frame Server Racks | Open design prevents cable tangles and blockages, improving airflow and cooling efficiency. | Easier access for maintenance and upgrades due to open structure. | Ideal for non-sensitive environments; cost-effective; supports both lightweight and heavy equipment. |

| Enclosed Server Racks | May restrict airflow due to enclosed design, potentially causing hotspots. | Provides security but can limit quick access to equipment. | Suitable for environments requiring physical security. |

| Rack Mounting | Facilitates organized cable management, reducing airflow obstruction. | Allows structured installation and easier maintenance access. | Common in data centers and enterprise setups. |

| Desktop Mounting | Limited airflow considerations due to small scale setups. | Convenient for small setups but less scalable. | Suitable for small offices or home networks. |

| DIN Rail Mounting | Typically used in industrial environments; airflow depends on enclosure design. | Easy installation in cabinets; good for automation setups. | Specialized mounting for industrial network switches. |

Voltage and Plug Compatibility in PDUs

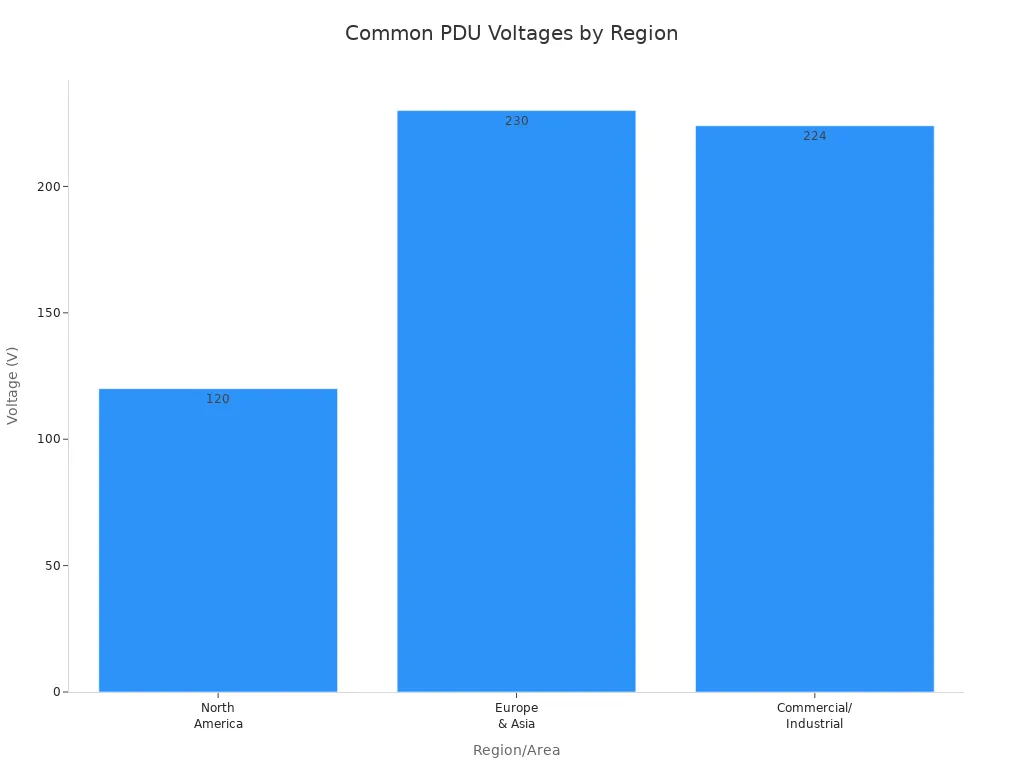

Voltage and plug compatibility are critical for seamless integration with existing power infrastructure. In North America, most business PDUs operate at 120 volts and use NEMA 5-15 plugs rated at 15 amps. Europe and Asia typically use 220 to 240 volts, with C13 connectors for standard IT equipment and C19 connectors for higher power devices. Larger servers may require 208 volts for increased capacity, often using NEMA L6-20P input plugs.

Businesses must match the PDU’s input and output connectors to the facility’s power sources and the equipment’s power cords. Locking power cables with mechanisms like P-Lock or A-Lock prevent accidental disconnections, enhancing reliability. Compatibility checks should include power ratings, connector types, and the specific voltage and current requirements of all connected devices.

- Assess the existing power setup and limitations.

- Match power ratings and connectors to prevent electrical hazards.

- Ensure outlet types and configurations align with equipment power cords.

- Consider monitoring and management features for efficient power utilization.

Essential PDU Safety and Protection Features

Safety and protection features are vital for safeguarding business equipment and maintaining operational reliability. Business-grade PDUs should include overcurrent protection through built-in circuit breakers, which automatically shut off power when current exceeds safe limits. Surge protection guards against damaging voltage spikes, while heat-resistant and fireproof materials withstand high temperatures.

- Overcurrent protection prevents overheating and fire hazards.

- Surge protection uses devices like Metal Oxide Varistors (MOVs) and Transient Voltage Suppressors (TVS) to absorb and clamp voltage spikes.

- Weatherproof and shockproof designs with IP ratings protect against moisture and electric shock.

- UL certification ensures compliance with recognized electrical safety standards.

- Ventilation slots allow airflow and prevent overheating.

Circuit breakers and surge protection work together to reduce the risk of equipment damage. Circuit breakers shut down outlets during unsafe conditions, while surge protection devices handle high-energy discharges from lightning or voltage impulses. Intelligent PDUs add remote monitoring and control, enabling proactive management of power conditions and further reducing risks.

Regular inspections, avoiding daisy chaining, and limiting loads to a safe percentage of rated capacity are best practices for maintaining a safe power distribution environment.

Common PDU Buying Mistakes

Underestimating Power Needs

Many businesses miscalculate their power requirements, often relying on equipment nameplate ratings or overlooking actual usage patterns. This mistake can result in overloaded circuits, unexpected downtime, and increased operational costs. The following table highlights frequent errors in estimating power needs:

| Common Mistake | Explanation | Impact / Consequence |

|---|---|---|

| Inaccurate Estimation of Power Capacities | Ignoring real consumption data and usage trends. | Overload, underutilization, higher costs. |

| Improper Choice of Power Equipment | Selecting mismatched UPS units or power factors. | Overloads, UPS trips, downtime. |

| Poor Cabling Between Servers and UPS | Using undersized cables, causing voltage drops and overheating. | System failures, shutdowns. |

| Failure in Designing Automatic Transfer | Incorrect neutral terminal handling. | System tripping, server freezing. |

| Excessive Load on Single PDU Point | Connecting too many high-power devices to one PDU. | Single point of failure, total power loss. |

Underestimating power needs can disrupt critical operations, create safety hazards, and even lead to legal non-compliance in regulated industries.

Overlooking Future Expansion

Businesses that fail to plan for growth often face costly upgrades and operational disruptions. Selecting a PDU with too few outlets or limited modularity restricts scalability. Companies should:

- Choose units with extra outlets and modular designs.

- Use intelligent models for real-time monitoring and remote management.

- Conduct site assessments to align capacity with future rack density.

Ignoring future needs increases downtime, staff strain, and budget pressures.

Ignoring Compatibility Issues

Compatibility checks are essential for seamless integration. Companies should:

- Match power chain specifications from utility feed to server profiles.

- Verify input current and voltage compatibility.

- Ensure compliance with safety standards and certifications.

- Confirm physical fit and mounting options.

Skipping these steps can cause equipment damage, breaker trips, or regulatory issues.

Neglecting Safety Features

Neglecting safety features exposes businesses to equipment failure, overheating, and power quality problems. Improper load balancing and poor maintenance increase the risk of outages and reduce equipment lifespan. Adhering to industry standards such as UL, CE, and NEMKO certifications ensures reliable and safe operation.

PDU Buying Checklist for Businesses

Evaluate Power Requirements

Businesses should follow a systematic approach to determine accurate power needs for a new PDU:

- List all devices that will connect, recording their power consumption in kilowatts or amperes.

- Use a three-phase PDU calculator to assess load distribution across phases.

- Apply derating factors for environmental conditions like temperature and altitude.

- Distribute loads evenly to avoid inefficiencies and equipment damage.

- Plan for future growth by selecting a PDU with extra capacity.

- Check compatibility with existing infrastructure, including voltage and mounting options.

- Add redundancy with backup PDUs or UPS units.

- Review and update requirements regularly as infrastructure changes.

Following these steps helps prevent overloads and ensures reliable power distribution.

Match Outlet Types and Quantity

- Assess the plug types and power ratings of all equipment.

- Choose a PDU with more outlets than currently needed to support future expansion.

- Select outlet types (IEC C13, C19, NEMA) that match equipment plugs.

- Consider modular designs for flexibility.

- Plan for redundancy and load balancing with dual power inputs.

- Use locking outlets and environmental monitoring for added safety.

Confirm Mounting and Rack Compatibility

- Measure rack dimensions to ensure the PDU fits.

- Select a mounting location that does not block airflow or access.

- Organize and label cables before installation.

- Secure the PDU with brackets and fasteners.

- Connect devices one by one, checking each for proper power delivery.

- Verify wiring and PDU functions after installation.

Proper mounting and cable management improve maintenance and cooling efficiency.

Verify Voltage and Plug Type

| Aspect | Details & Considerations |

|---|---|

| Plug Types & Standards | Match PDU plug to power source; use IEC or NEMA standards. Locking plugs prevent accidental disconnects. |

| Voltage & Phase | Identify single-phase or three-phase power. Use color codes for IEC 60309 plugs. |

| Receptacle Types & Count | Ensure enough compatible outlets for all devices, with extras for growth. |

| Power Cord Size | Choose appropriate cord length and gauge for amperage and layout. |

Ensure Safety and Protection Features

- Verify certifications such as UL, CE, and RoHS.

- Ensure compliance with IEC, ISO, and NEMA standards.

- Confirm the PDU matches voltage, power, and phase requirements.

- Specify the number and type of outlets needed.

- Look for locking outlets and hot-swappable monitoring modules.

- Use environmental sensors for temperature and humidity.

- Implement outlet-level metering and remote monitoring.

- Consider remote control features for quick response to issues.

These features protect equipment, reduce downtime, and support safe operation.

Selecting the right PDU supports business reliability and growth. Industry experts recommend the following tips:

- Match voltage, phase, and outlet types to equipment.

- Prioritize certifications like UL and CE.

- Choose scalable, rack-compatible designs.

- Evaluate customer support and warranty options.

A careful approach ensures safe, efficient power distribution.

FAQ

What is the difference between a basic PDU and a smart PDU?

A basic PDU distributes power without monitoring or control features. A smart PDU offers remote monitoring, outlet control, and advanced management for improved oversight.

How can a business determine the correct PDU size?

A business should total the power consumption of all connected devices, apply an 80% safety margin, and select a PDU with sufficient capacity for current and future needs.

Are all PDUs compatible with every server rack?

Not all PDUs fit every rack. Businesses must check rack dimensions, mounting options, and connector types before purchasing to ensure proper compatibility.

Tip: Always verify PDU specifications against your rack and equipment requirements before buying.

Post time: Aug-04-2025