Choosing the right Power Distribution Unit ensures uninterrupted operations in manufacturing plants. A Basic PDU supports fundamental power needs, while an Intelligent PDU offers advanced monitoring and control. These units enhance safety, optimize energy use, and reduce downtime, making them critical for maintaining productivity and operational efficiency in demanding industrial environments.

Key Takeaways

- Picking the right Power Distribution Unit (PDU) is important. It helps keep manufacturing plants running without interruptions. Think about your power needs now and in the future when choosing one.

- Find PDUs with good safety features like circuit breakers. Overload protection is also important. These features keep people and equipment safe from electrical dangers.

- Buying energy-saving PDUs can save a lot of money. They use less energy, prevent delays, and cut repair costs. This helps your wallet and the environment.

Overview of Industrial Power Distribution Units

What Are Industrial Power Distribution Units?

Industrial Power Distribution Units (PDUs) are specialized devices designed to manage and distribute electrical power efficiently across manufacturing facilities. These units ensure stable power delivery by cleaning up noisy power signals, which is critical for sensitive machinery. They feature modular designs that allow flexible installation and system expansion, catering to diverse manufacturing needs. Built with heavy-duty materials like impact-modified thermoplastic and stainless steel, PDUs withstand harsh factory environments and protect against contaminants.

Modern PDUs integrate advanced capabilities, such as safety interlocks and connectivity options, to enhance operational safety and control. Compliance with industry standards, including IEC 60950-1 and IEC 62368-1, ensures reliability and adherence to safety regulations. These units also align with the EU low-voltage directive (LVD), making them suitable for global applications.

| Feature/Capability | Description |

|---|---|

| Noise Reduction | Industrial PDUs clean up noisy power signals, ensuring stable power delivery. |

| Safety Interlocks | Integrated safety interlocks enhance operational safety in industrial environments. |

| Connectivity and Control | Unique connectivity and control options tailored for power management in industrial settings. |

Why Are They Essential for Manufacturing Plants?

Industrial PDUs play a vital role in maintaining the efficiency and safety of manufacturing operations. They distribute power to various units based on demand, preventing overloads and ensuring uninterrupted workflows. Enhanced safety features, such as UPS systems and fire detection mechanisms, protect operators and equipment from electrical hazards.

These units also monitor power consumption and leakage, enabling manufacturers to optimize energy use and reduce costs. Their modular construction accommodates standard dimensions, allowing flexible configurations that adapt to changing production needs. By shielding critical electrical components from environmental hazards, PDUs ensure reliability and consistent operating conditions.

Manufacturing plants benefit from PDUs’ cost-effectiveness, as they reduce installation time and eliminate field labor. Their compliance with IBC, IEC, and ComCheck standards further enhances safety and reliability. In environments where productivity and safety are paramount, PDUs provide the infrastructure needed to meet these demands.

Key Features to Look For

Load Capacity and Scalability

Load capacity and scalability are critical factors when selecting a Power Distribution Unit. These features ensure that the unit can handle the current and future power demands of a manufacturing plant. Modular designs allow seamless integration with existing infrastructures, enabling facilities to expand without significant reconfigurations.

- Three-phase power systems are particularly advantageous for growing operations. They support higher energy demands and facilitate the addition of new equipment without disrupting workflows.

- The increasing demand for automation and regulatory compliance has driven the development of scalable PDUs, making them essential for modern manufacturing environments.

By prioritizing scalability, manufacturers can future-proof their operations and adapt to evolving energy requirements.

Safety Features and Certifications

Safety is paramount in industrial settings. Power Distribution Units incorporate features like circuit breakers and overload protection to safeguard equipment and personnel. These units also provide detailed power usage data, helping operators identify potential risks before they escalate.

Compliance with industry standards, such as IEC and IBC certifications, ensures that PDUs meet stringent safety requirements. By adhering to these standards, manufacturers can maintain operational reliability while minimizing the risk of electrical hazards.

Energy Efficiency and Cost Savings

Energy efficiency directly impacts operational costs. Modern Power Distribution Units are designed to optimize energy use, reducing waste and lowering utility bills. Features like real-time monitoring and energy management systems enable manufacturers to track consumption and identify inefficiencies.

Cost savings extend beyond energy bills. Efficient PDUs reduce downtime and maintenance expenses, contributing to overall productivity. Investing in energy-efficient units ensures long-term financial and environmental benefits.

Compatibility with Existing Systems

Compatibility is a crucial consideration when integrating a Power Distribution Unit into a manufacturing plant. Units must align with existing electrical systems to avoid costly modifications. Modular PDUs offer flexible configurations, making them suitable for diverse operational setups.

By choosing compatible units, manufacturers can streamline installation processes and minimize disruptions. This approach ensures a smooth transition and enhances the overall efficiency of the facility.

Top Manufacturers and Their Products

Eaton and Their Leading Products

Eaton has established itself as a global leader in the power distribution industry. The company offers a wide range of Power Distribution Units designed to meet the demands of modern manufacturing plants. Eaton’s PDUs are known for their robust construction, advanced safety features, and energy efficiency.

The global power distribution units market, including Eaton’s contributions, is projected to grow significantly, reaching $6.2 billion by 2032 at a CAGR of 7.1%. Eaton’s solutions cater to diverse industries, ensuring reliable power delivery and operational efficiency. Although specific product reliability studies are unavailable, Eaton’s reputation as a major player in the market underscores its commitment to quality and innovation.

Key features of Eaton’s PDUs include:

- Modular designs that allow seamless integration with existing systems.

- Advanced monitoring capabilities for real-time power management.

- Compliance with international standards, ensuring safety and reliability.

Eaton’s products are particularly suited for manufacturing plants requiring scalable and energy-efficient solutions. Their focus on innovation and adaptability makes them a preferred choice for many industrial applications.

Vertiv and Their Leading Products

Vertiv is another prominent name in the power distribution sector, particularly recognized for its high-performance PDUs tailored for critical applications. The company emphasizes reliability, safety, and space optimization, making its products ideal for manufacturing plants and data centers.

Vertiv’s PDUs offer several advantages:

- Higher reliability ratings, ensuring uninterrupted operations.

- Maintenance-friendly designs that allow servicing without compromising redundancy.

- Custom transformers to meet specific operational needs.

| Key Benefits | Description |

|---|---|

| Higher reliability ratings | Targets high uptime, crucial for meeting high availability demands. |

| Maintenance without redundancy compromise | Enables servicing without affecting power supply to other tenants. |

| Safe load modifications | Allows operators to modify specific loads while maintaining overall power. |

| Reduced white-space impact | Minimizes footprint, optimizing space utilization in industrial setups. |

Vertiv’s focus on innovation and customer-centric solutions has positioned it as a key player in the market. Its products are particularly beneficial for facilities requiring high uptime and operational flexibility.

Schneider Electric and Their Leading Products

Schneider Electric, through its APC brand, has earned a reputation for delivering reliable and innovative power management solutions. The company offers a diverse range of PDUs, including basic, metered, switched, and advanced smart PDUs with IoT capabilities. These products cater to various industrial needs, ensuring comprehensive power management.

Schneider Electric’s APC PDUs stand out for their advanced features:

- Real-time monitoring and modular scalability enhance reliability and uptime.

- EcoStruxure IT readiness in models like the APC APDU9953 improves energy efficiency.

- Sustainability-focused designs, reflecting the company’s commitment to environmental responsibility.

The company has received numerous awards for sustainability and product design, further solidifying its position as a trusted name in the industry. Schneider Electric’s PDUs are ideal for manufacturing plants seeking energy-efficient and technologically advanced solutions.

Technical Specifications and Applications

Voltage and Current Ratings

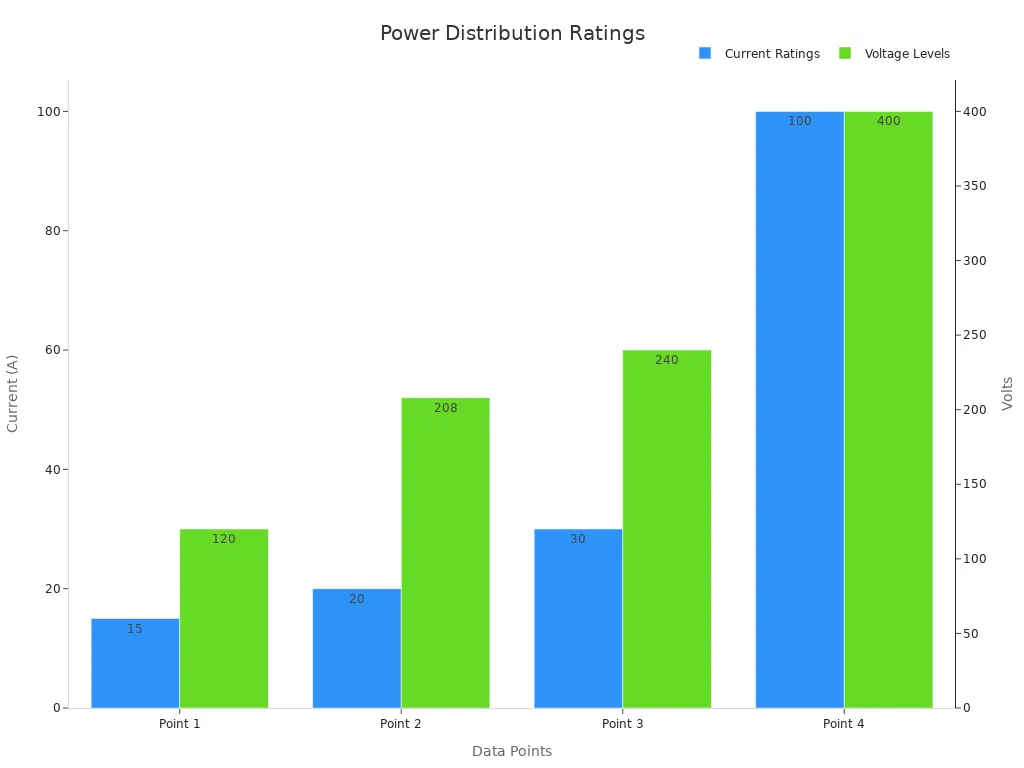

Industrial Power Distribution Units are designed to handle a wide range of voltage and current capacities, ensuring compatibility with diverse manufacturing environments. Common current ratings include 15A, 20A, 30A, and up to 100A, while voltage compatibility spans 120V, 208V, 240V, and 400V. These ratings allow manufacturers to select units tailored to their specific power requirements.

The “80% rule” is a critical guideline for capacity utilization, ensuring that units operate efficiently without exceeding safe limits. Compatibility with UPS systems further enhances reliability by providing backup power during outages. The chart below illustrates the relationship between current ratings and voltage levels for various PDUs:

Environmental Durability (Temperature, Humidity, etc.)

Manufacturing plants often operate in challenging environments, making durability a key consideration. Power Distribution Units must withstand extreme temperatures, high humidity, and exposure to dust or chemicals. Many units feature enclosures rated for IP54 or higher, offering protection against water and particulate ingress.

Temperature tolerance typically ranges from -20°C to 60°C, ensuring reliable performance in both cold storage facilities and high-heat production lines. Humidity resistance prevents corrosion and electrical failures, safeguarding equipment in moisture-prone areas. These specifications ensure that PDUs maintain operational integrity under demanding conditions.

Applications in Different Manufacturing Scenarios

The versatility of Power Distribution Units makes them indispensable across various manufacturing scenarios. Monitored PDUs provide real-time power consumption data, ideal for energy-intensive industries. Automatic Transfer Switch (ATS) PDUs ensure uninterrupted power for critical operations, such as pharmaceutical production or semiconductor manufacturing.

Hot-swap PDUs allow component replacement without downtime, benefiting high-availability environments. Intelligent PDUs, with advanced monitoring and control capabilities, support smart factories and Industry 4.0 initiatives. The table below highlights the applications of different PDU types:

| Type of PDU | Definition | Applications |

|---|---|---|

| Monitored (or Smart) PDU | Provides real-time monitoring and data logging of power consumption. | Large Data Centers, Financial Institutions, Manufacturing |

| Automatic Transfer Switch | Automatically switches between two power sources for continuous supply. | Critical Infrastructure, Broadcasting, High Availability Systems |

| Hot-Swap PDU | Allows component replacement without shutting down connected equipment. | Data Centers, High Availability Environments, Critical Operations |

| Intelligent PDU | Advanced monitoring, control, and management capabilities. | Enterprise Data Centers, Colocation Facilities, Smart Buildings |

| Rack-Mount PDU | Designed for mounting in server racks. | Server Rooms, Network Closets, Lab Environments |

Pros and Cons of Each Unit

Advantages of Eaton Power Distribution Units

Eaton Power Distribution Units offer several benefits that make them a preferred choice for manufacturing plants:

- Their dependable performance ensures equipment remains powered and protected, minimizing downtime.

- Real-time monitoring capabilities provide insights into power usage, enabling effective energy management.

- Flexible designs allow seamless integration into various rack setups, accommodating diverse operational needs.

- Advanced monitoring features enhance efficiency, particularly in manufacturing environments where precision is critical.

- Industry professionals commend Eaton for its commitment to innovation and reliability, which has fostered a loyal customer base.

Eaton’s focus on delivering high-quality products and exceptional customer service has further solidified its reputation. Continuous improvement efforts have also contributed to enhanced customer satisfaction, making Eaton a trusted name in the industry.

Disadvantages of Eaton Power Distribution Units

Despite their strengths, Eaton PDUs have some limitations:

- The initial cost of Eaton units can be higher compared to competitors, which may deter budget-conscious buyers.

- Some users report that the advanced features require a steep learning curve, especially for operators unfamiliar with modern power management systems.

- Limited availability of certain models in specific regions can pose challenges for global manufacturers.

While these drawbacks exist, they are often outweighed by the units’ overall performance and reliability.

Advantages of Vertiv Power Distribution Units

Vertiv PDUs are designed with reliability and safety in mind, offering several advantages:

- Higher reliability ratings ensure uninterrupted operations, which is crucial for manufacturing plants with high uptime requirements.

- Maintenance-friendly designs allow servicing without compromising redundancy, reducing operational disruptions.

- Custom transformers cater to specific operational needs, providing tailored solutions for diverse industries.

- Operators can safely modify specific loads while maintaining overall power, enhancing flexibility.

- Compact designs minimize white-space impact, optimizing space utilization in industrial setups.

Vertiv’s emphasis on innovation and customer-centric solutions has positioned it as a key player in the power distribution market.

Disadvantages of Vertiv Power Distribution Units

While Vertiv PDUs excel in many areas, they are not without limitations:

- The compact design, while space-saving, may limit scalability in some configurations.

- Custom transformers, though beneficial, can increase costs and lead times for specialized orders.

- Some users find the initial setup process complex, requiring additional training or support.

These challenges highlight the importance of evaluating specific operational needs before selecting a Vertiv unit.

Advantages of Schneider Electric Power Distribution Units

Schneider Electric PDUs, particularly through their APC brand, stand out for their advanced features and energy efficiency:

- Real-time monitoring and modular scalability enhance reliability and uptime, making them ideal for dynamic manufacturing environments.

- Integration with energy management systems, such as EcoStruxure IT, optimizes energy usage and reduces costs.

- Sustainability-focused designs reflect the company’s commitment to environmental responsibility, aligning with modern industry trends.

- MPDUs (Metered Power Distribution Units) provide visibility into energy consumption patterns, aiding in cost reduction and predictive maintenance.

- Schneider Electric’s expertise in environmental risks and its strong market presence further enhance its competitive edge.

These features make Schneider Electric PDUs essential for facilities prioritizing energy efficiency and technological advancement.

Disadvantages of Schneider Electric Power Distribution Units

Despite their numerous benefits, Schneider Electric PDUs have some drawbacks:

- The advanced features and IoT capabilities can result in higher upfront costs, which may not suit all budgets.

- Some users report that integrating EcoStruxure IT with existing systems requires additional resources and expertise.

- The focus on sustainability and advanced technology may lead to over-engineering for simpler applications, increasing complexity unnecessarily.

While these disadvantages exist, Schneider Electric’s focus on innovation and energy efficiency often outweighs these concerns for many manufacturers.

Comparison Table for Easy Reference

Key Metrics for Comparison (Performance, Cost, Reliability)

The table below consolidates critical metrics to help manufacturers evaluate and compare industrial Power Distribution Units (PDUs). These metrics focus on performance, cost, and reliability, ensuring informed decision-making.

| Metric | Eaton | Vertiv | Schneider Electric |

|---|---|---|---|

| Performance | Advanced monitoring, modular scalability, and high energy efficiency. | High reliability ratings, custom transformers, and safe load modifications. | Real-time monitoring, IoT integration, and EcoStruxure IT compatibility. |

| Cost | Higher upfront cost but long-term savings through energy efficiency. | Moderate cost with options for tailored configurations. | Premium pricing due to advanced features and sustainability focus. |

| Reliability | Proven track record with robust designs and compliance with global standards. | Maintenance-friendly and designed for high uptime environments. | Strong market presence and award-winning sustainability initiatives. |

| Energy Efficiency | Optimized energy use with real-time tracking and modular designs. | Efficient power management with minimal white-space impact. | Industry-leading energy management systems and predictive maintenance. |

| Scalability | Seamless integration with existing systems for future expansion. | Compact designs with limited scalability in some configurations. | Modular scalability for dynamic manufacturing needs. |

Summary of Findings

Eaton, Vertiv, and Schneider Electric each bring unique strengths to the table. Eaton excels in energy efficiency and scalability, making it ideal for facilities prioritizing long-term cost savings. Vertiv stands out for its reliability and maintenance-friendly designs, catering to high-uptime environments. Schneider Electric leads in innovation and sustainability, offering advanced IoT-enabled solutions for modern manufacturing plants.

Key Takeaway: Manufacturers should prioritize their specific operational needs—whether it’s energy efficiency, reliability, or advanced features—when selecting a PDU. While Eaton suits scalable and cost-conscious setups, Vertiv is best for reliability-focused operations. Schneider Electric is the top choice for facilities embracing smart technologies and sustainability.

Selecting the right Power Distribution Unit ensures operational efficiency and safety in manufacturing plants. The global PDU market, projected to reach $4.24 billion by 2030, highlights the growing demand for tailored solutions. Manufacturers should assess their power needs, prioritize scalability, and choose units that align with their operational goals for long-term success.

FAQ

What is the lifespan of an industrial Power Distribution Unit (PDU)?

The lifespan of a PDU typically ranges from 10 to 15 years. Proper maintenance and adherence to manufacturer guidelines can extend its operational life.

Can PDUs be customized for specific manufacturing needs?

Yes, many manufacturers offer customizable PDUs. Options include tailored voltage ratings, modular designs, and additional safety features to meet unique operational requirements.

How often should PDUs undergo maintenance checks?

PDUs should undergo maintenance checks every 6 to 12 months. Regular inspections ensure optimal performance and help identify potential issues before they escalate.

Post time: May-06-2025