Choosing between a PDU and a power strip can make a significant difference in electrical safety and performance. Power strips, often used in homes and offices, link to nearly 51,000 home fires each year due to improper use or overloading. In contrast, a Basic PDU offers improved safety and reliability for environments with higher power demands. Selecting the right device helps prevent overloads, reduces fire risks, and ensures equipment receives stable power, especially in critical settings like data centers.

Key Takeaways

- PDUs offer stronger safety features like circuit breakers and overload protection, making them ideal for critical and industrial environments.

- Power strips suit everyday home and office use with basic surge protection but lack advanced safety and monitoring.

- Choosing the right device prevents overloads, reduces fire risks, and protects valuable equipment.

- PDUs support more outlets, higher voltages, and remote monitoring, enabling better power management and control.

- Avoid daisy-chaining power strips or PDUs to prevent fire hazards and electrical failures.

- Look for safety certifications like UL or CE to ensure the device meets strict safety standards.

- Regular maintenance and proper load management extend device lifespan and improve safety.

- Investing in a PDU provides long-term reliability, scalability, and peace of mind for demanding power needs.

Key Differences Between PDUs and Power Strips

Safety Implications

Electrical safety organizations highlight significant differences in the safety features of PDUs and power strips. PDUs include industrial-grade safety mechanisms such as circuit breakers and resettable fuses. These components provide robust overload protection, which is essential in environments with high power demands. Power strips, on the other hand, usually offer only basic surge protection and often lack circuit breakers or resettable fuses. This limitation makes power strips less suitable for industrial or critical settings where equipment reliability and safety are paramount.

PDUs also support remote monitoring capabilities. This feature allows users to track power usage and identify potential overloads before they become hazardous. Power strips do not offer this level of monitoring or control. As a result, PDUs deliver a higher standard of safety for data centers, server rooms, and industrial environments, while power strips remain appropriate for residential or light office use.

Note: Choosing the right device for the environment can prevent overloads, reduce fire risks, and protect valuable equipment.

| Aspect | PDUs (Power Distribution Units) | Power Strips |

|---|---|---|

| Construction Material | Industrial-grade steel, robust for heavy-duty use | Typically plastic, designed for medium-duty |

| Overload Protection | Industrial-grade overload protectors, resettable fuses, MCBs | Usually only surge protection, no industrial-grade overload protection |

| Voltage Support | Supports higher voltages including three-phase (208V/400V) | Usually single-phase power only |

| Safety Features | Advanced safety features including circuit breakers and fuses | Basic safety features, mainly surge protection |

| Application Environment | Industrial, data centers, server rooms | Residential, office, light-duty environments |

| Monitoring & Control | Advanced monitoring, remote access, load balancing | No advanced monitoring or control |

| Durability | Steel construction, rack-mountable | Plastic casing, no specific mounting |

Primary Use Cases

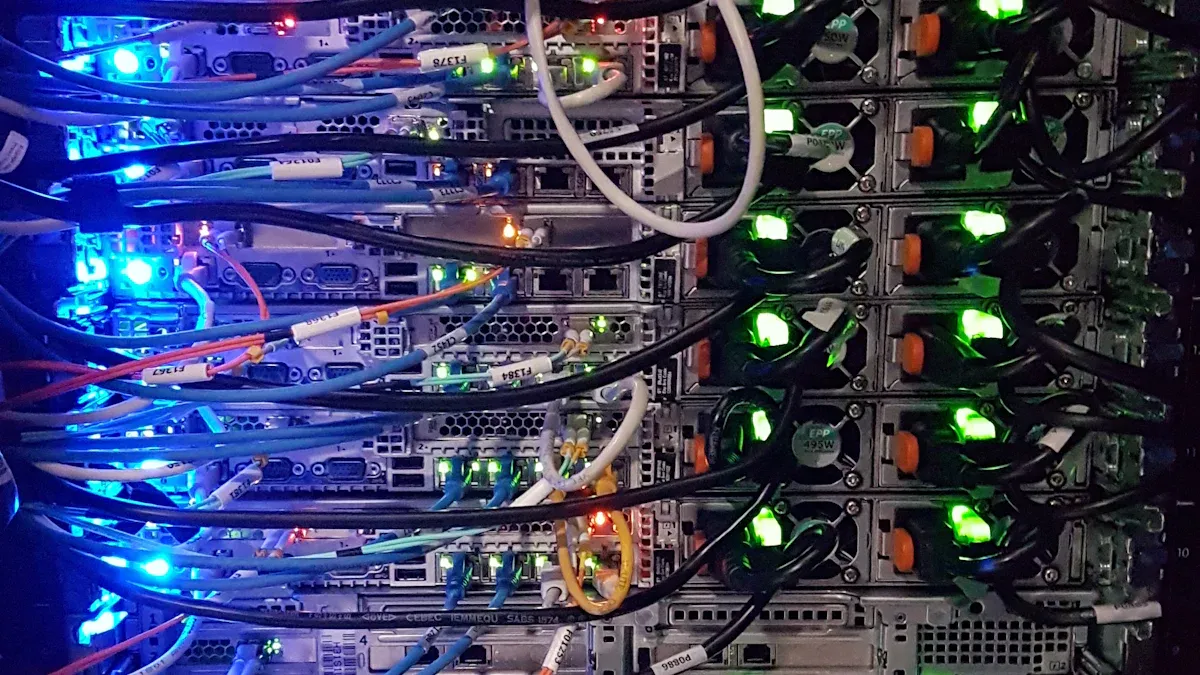

PDUs and power strips serve different environments and equipment needs. PDUs appear most often in industrial settings, data centers, and server rooms. These locations require reliable power distribution for rack-mounted equipment such as IT servers, LCD drawers, and network switches. The design of a PDU supports heavy-duty use, higher voltages, and even three-phase power, making it ideal for demanding applications.

Power strips, by contrast, fit best in residential homes, regular offices, and shops. People use them to power medium-duty appliances like home entertainment systems, kitchen devices, lighting, and desktop computers. Power strips are not designed for industrial or outdoor use and do not support the same range of voltages or equipment as PDUs.

| Environment/Application | PDUs (Power Distribution Units) | Power Strips |

|---|---|---|

| Typical Use Environment | Industrial settings such as data management centers | Residential homes, regular offices, shops |

| Common Equipment Connected | Rack-mount equipment: IT servers, LCD drawers, network switches | Medium-duty appliances: home entertainment, kitchen appliances, lighting, desktop computers |

| Design Purpose | Heavy-duty, industrial use; can handle higher voltage/current, including three-phase power | Medium-duty use for everyday appliances |

| Additional Features | Suitable for weather-proof cables and outdoor extension cords | Not typically designed for industrial or outdoor use |

Core Functional Differences

The construction and functionality of PDUs and power strips differ in several key areas. PDUs use steel for their housing, which provides durability and supports rack-mounting in vertical or horizontal configurations. They offer a wide range of outlet options, from 4 to 48, and support both domestic and international-grade inlets and outlets. The wire gauge in a PDU ranges from 14 AWG to 6 AWG, allowing it to handle higher currents and voltages, including three-phase power.

Power strips typically use plastic casings and offer fewer outlets, usually between 2 and 8. Their wire gauge is generally 14 AWG, which suits medium-duty applications. Power strips support only single-phase voltages (110V/208V/230V) and lack advanced safety features like resettable fuses or MCBs. They do not provide remote monitoring, load balancing, or advanced control options.

| Aspect | PDUs (Power Distribution Units) | Power Strips |

|---|---|---|

| Construction Material | Typically made of steel | Usually made of plastic |

| Wire Gauge Ratings | Range from 14 AWG to 6 AWG, supporting heavy-duty applications | Typically 14 AWG, suitable for medium-duty |

| Voltage Ratings | Support higher voltages including 208V/400V three-phase | Support lower single-phase voltages (110V/208V/230V) |

| Safety Features | Include overload protectors, resettable fuses, or MCBs | Often have surge protectors but lack fuses or MCBs |

| Physical Configuration | Rack-mountable (0U, 1U, 2U), vertical or horizontal, many outlets (4-48) | Simple rectangular blocks, fewer outlets (2-8), no specific mounting |

| Outlet/Inlet Types | Domestic and international-grade (IEC 60309, IEC C13/C19) | Usually country-specific inlets and outlets |

| Typical Use | Industrial environments, data centers, rack equipment | Residential, offices, shops, home appliances |

Tip: For environments with high power demands or critical equipment, a PDU offers advanced safety, monitoring, and control features that a standard power strip cannot match.

PDU Overview

What Is a PDU?

A Power Distribution Unit, or PDU, serves as a central device for distributing electrical power to multiple connected devices. Electrical engineering standards define a PDU as a device that ensures safe and reliable power delivery, meeting strict requirements for industrial control equipment and machinery safety. These standards include UL508, EN 60204-1, and IEC/UL/EN 61010-1, among others. The PDU protects both personnel and equipment by incorporating features such as overcurrent protection, emergency machine-off controls, and electromagnetic compatibility. In practical terms, a PDU takes alternating current (AC) from a single source and distributes it to several devices, such as servers, routers, and switches. This organized approach to power delivery supports environments where safety and reliability are critical.

| Standard | Requirement Example |

|---|---|

| UL508 | Industrial control equipment safety |

| EN 60204-1 | Electrical equipment of machines |

| IEC/UL/EN 61010-1 | Safety for electrical equipment |

PDUs play a vital role in data centers and server rooms, where ordinary power strips cannot meet the demands for safety and reliability.

Types of PDUs

PDUs come in several types, each designed for specific operational needs. The main categories include basic, metered, switched, and intelligent PDUs.

Basic PDUs

Basic PDUs provide straightforward power distribution without advanced monitoring or control features. They function much like large power strips but use industrial-grade materials and safety mechanisms. These units suit small server rooms or environments with on-site IT staff who can monitor power usage directly.

Metered PDUs

Metered PDUs display real-time power consumption data, such as voltage, current, and energy usage. This information helps prevent overloads and supports efficient energy management. Metered PDUs are valuable in secure data centers where local monitoring is essential.

Switched PDUs

Switched PDUs allow remote control of individual outlets. Users can power cycle equipment, perform staged power-ups, or lock out outlets to prevent unauthorized use. These features benefit large-scale data centers and remote sites without on-site IT teams.

Intelligent PDUs

Intelligent PDUs, sometimes called managed or monitored PDUs, combine advanced monitoring with remote management. They offer network connectivity, environmental sensing, and high-accuracy power data. Intelligent PDUs support billing-grade measurement and enable proactive management of power loads.

| PDU Type | Key Features |

|---|---|

| Basic | Simple distribution, robust build, no monitoring |

| Metered | Real-time local power data, overload prevention |

| Switched | Remote outlet control, power cycling, staged power-up |

| Intelligent | Network monitoring, environmental sensing, billing-grade accuracy, advanced management |

PDU Applications

PDUs see widespread use in commercial and industrial settings. They distribute power reliably to critical IT equipment, such as servers and network switches, within racks or cabinets. Common application environments include:

- Data centers

- Server rooms

- Colocation facilities

- Edge computing locations

Different PDU types address various operational needs. Basic PDUs fit small server rooms, while metered and intelligent PDUs serve high-density data centers. Switched PDUs provide remote control for large-scale or remote sites. In all cases, PDUs ensure organized, safe, and efficient power distribution for IT infrastructure.

Power Strip Overview

What Is a Power Strip?

A power strip is a device that expands the number of available electrical outlets from a single wall socket. It allows users to connect multiple electronic devices in areas where outlets are limited. Most power strips feature a compact, rectangular design and include a built-in on/off switch for convenience. Manufacturers typically design power strips for residential and office environments, where users need to power several low- to medium-duty devices at once. While power strips increase outlet availability, their safety features and power management capabilities vary by type.

Types of Power Strips

Power strips come in several forms, each offering different levels of protection and functionality. Understanding these types helps users select the right device for their needs.

Basic Power Strips

Basic power strips provide a simple solution for connecting multiple devices. They primarily serve to expand outlet capacity without offering advanced safety features. Most basic models lack surge protection and do not monitor energy usage. Users often choose these strips for temporary setups or low-risk environments, such as powering lamps or small appliances.

Surge-Protected Power Strips

Surge-protected power strips add an extra layer of safety by shielding connected devices from voltage spikes. These strips contain built-in surge suppressors that absorb excess energy during electrical surges, helping to prevent damage to sensitive electronics. Many entertainment centers and home offices rely on surge-protected strips to safeguard computers, televisions, and audio equipment.

Smart Power Strips

Smart power strips, also known as automatic or advanced power strips, offer enhanced safety and energy efficiency. These devices detect when connected equipment enters standby mode and automatically cut off power, reducing phantom energy consumption. Smart strips often include surge protection and programmable timers. By eliminating standby power waste, they can lower electricity bills by up to 30% annually. Environmentally conscious consumers increasingly prefer smart power strips for their ability to combine safety with energy savings.

Tip: Smart power strips not only protect devices from electrical surges but also help reduce unnecessary energy use, making them a smart investment for both safety and sustainability.

Power Strip Applications

Power strips play a vital role in both residential and office settings. They enable users to power multiple devices from a single outlet, which proves especially useful in areas with limited plug availability. In home offices, power strips with multiple outlets and USB ports support computers, printers, and phones. Entertainment centers benefit from surge-protected strips that safeguard expensive electronics. Kitchens often use power strips with high-powered outlets for appliances.

The following table summarizes common applications and features:

| Environment | Common Applications | Additional Features and Mounting Options |

|---|---|---|

| Residential | Laptops, smartphones, tablets, kitchen appliances, entertainment systems | Desk, wall, or floor mounting; multiple outlet standards |

| Office | Computers, printers, phones, electronic equipment | Rack, wall, or workbench mounting; hardwiring, vertical mounts |

| General Use | Extending AC outlets where plugs are limited | Surge and noise protection available |

Power strips remain essential for extending outlet capacity and protecting devices in everyday environments. Users should select the appropriate type based on their safety and energy management needs.

PDU vs. Power Strip: Safety Features

Overload and Surge Protection

Electrical overloads and surges pose significant risks to both equipment and safety. PDUs often feature industrial-grade overload protection, which includes mechanisms that detect excessive current and disconnect power before damage occurs. This protection is essential in environments with high power demands, such as server rooms and data centers. Many PDUs also support surge protection, shielding sensitive electronics from voltage spikes caused by lightning or grid fluctuations.

Power strips typically offer basic surge protection. Manufacturers design these devices for residential and office use, where power demands remain moderate. Surge-protected power strips use built-in suppressors to absorb excess energy, protecting computers, televisions, and small appliances. However, most power strips lack advanced overload detection, making them less suitable for critical or industrial applications.

Surge protection helps prevent costly equipment failures and data loss, especially in areas prone to electrical disturbances.

Circuit Breakers and Fuses

Circuit breakers and fuses serve as vital safety components in power distribution devices. PDUs incorporate resettable circuit breakers or fuses that automatically disconnect power when current exceeds safe limits. This feature allows users to restore power quickly after resolving the issue, minimizing downtime and preventing electrical fires. In industrial settings, circuit breakers provide an extra layer of protection for expensive IT infrastructure.

Power strips may include simple fuses or basic circuit breakers, but these components often lack the robustness found in PDUs. Many basic power strips do not feature resettable breakers, requiring users to replace blown fuses manually. Advanced models may offer circuit breakers, but their capacity remains limited compared to PDUs. For environments with multiple high-powered devices, PDUs deliver superior protection and reliability.

Fire Resistance and Build Quality

Manufacturers use specialized materials and certifications to enhance fire resistance and build quality in both PDUs and power strips. Flame-retardant plastics, aluminum alloy, and steel chassis provide durability and help dissipate heat. Internal components, such as flame-retardant PC modules and fiberglass-reinforced epoxy laminate PCBs, further improve safety by resisting high temperatures and electrical faults.

The following table summarizes key aspects of fire resistance and build quality:

| Aspect | Details |

|---|---|

| Materials | Flame-retardant plastics, aluminum alloy, steel chassis, flame-retardant PC modules, fiberglass PCBs |

| Certifications | UL, CE, RoHS, CSA, ISO9001, VDE |

| Importance | Ensures durability, fire resistance, and reliability for home, office, and industrial environments |

UL certification stands out as a critical indicator of safety. Products that carry UL certification have passed rigorous tests for fire hazards, electrical shock, and injury risks. This independent evaluation assures users that the device meets high standards for fire resistance and build quality. PDUs and power strips with these certifications offer greater peace of mind and long-term reliability.

Devices with proper materials and certifications help prevent fire hazards and ensure safe operation in any environment.

Monitoring and Alerts

Modern power distribution devices offer more than just basic power delivery. Monitoring and alert features play a crucial role in maintaining electrical safety and operational efficiency. These capabilities allow users to detect issues early, prevent equipment damage, and respond quickly to potential hazards.

PDUs often include advanced monitoring systems. These systems track real-time data such as voltage, current, power consumption, and temperature. Many PDUs display this information on a local screen or transmit it to a central management platform. Facility managers can review historical data, identify trends, and spot irregularities before they escalate into serious problems.

Some PDUs also provide automated alerts. When the system detects abnormal conditions—such as an overload, high temperature, or voltage fluctuation—it sends notifications via email, SMS, or network management software. This immediate feedback enables staff to take corrective action, reducing the risk of downtime or fire hazards.

Key monitoring and alert features found in PDUs include:

- Real-time power usage monitoring

- Threshold-based alerts for overloads or temperature spikes

- Remote access to monitoring data

- Event logging for compliance and troubleshooting

Power strips, in contrast, rarely offer built-in monitoring or alert functions. Most models lack displays or connectivity. Users must rely on visual inspection or external devices to detect issues. Some advanced smart power strips may provide basic energy monitoring, but these features remain limited compared to those found in PDUs.

The following table summarizes the differences in monitoring and alert capabilities:

| Feature | PDU | Power Strip |

|---|---|---|

| Real-time Power Monitoring | Yes (local display or remote access) | Rare, mostly unavailable |

| Automated Alerts | Yes (email, SMS, SNMP, etc.) | Not available |

| Event Logging | Yes | Not available |

| Remote Management | Yes | Limited or not available |

Tip: Facilities that require high uptime and safety should choose devices with robust monitoring and alert systems. These features help prevent costly outages and protect valuable equipment.

Effective monitoring and alert capabilities set PDUs apart in environments where safety and reliability matter most. By providing real-time insights and immediate notifications, these devices support proactive maintenance and rapid response to electrical issues.

PDU vs. Power Strip: Functionality and Control

Remote Management Capabilities

Remote management stands as a defining feature in advanced power distribution solutions. In modern IT environments, administrators often need to control power to equipment without being physically present. Switched and intelligent PDUs provide this capability through network connectivity, allowing users to turn outlets on or off, reboot devices, and monitor status from anywhere. This remote access proves invaluable in large data centers or distributed sites, where immediate response to power issues can prevent downtime and data loss.

Power strips, in contrast, do not offer remote management. Users must manually operate the on/off switch, which controls all outlets at once. This limitation makes power strips less suitable for environments that require rapid intervention or remote troubleshooting.

Power Monitoring and Reporting

Accurate power monitoring and detailed reporting help organizations optimize energy use and maintain safe operations. The following table highlights the differences in monitoring and reporting features between power strips and various PDU types:

| Device Type | Power Monitoring Capabilities | Reporting Features | Remote Access/Control |

|---|---|---|---|

| Power Strip | None | None | None |

| Basic PDU | None | None | None |

| Metered PDU | Local current meter (real-time load monitoring only) | No data accumulation or remote reporting | None |

| Monitored PDU | Remote real-time monitoring of voltage, power, load | Historical data review, alarm notifications | Network connectivity for remote monitoring |

| Switched PDU | Same as monitored PDU | Same as monitored PDU | Remote on/off control of individual outlets |

| Smart PDU (via upgrade) | Enhanced remote data access via wireless Smart Power Cables | Real-time data transmission and remote monitoring | Wireless remote monitoring and control |

Power strips lack any form of power monitoring or reporting. Metered PDUs display real-time load information locally, while monitored and switched PDUs enable remote access to power data, historical reviews, and alarm notifications. Smart PDUs further enhance these capabilities with wireless data transmission and advanced reporting.

Individual Outlet Control

Individual outlet control provides significant advantages in managing complex power environments. Switched and intelligent PDUs allow users to control each outlet independently, offering several key benefits:

- Remote management of individual outlets enables turning devices on or off and rebooting servers without physical presence.

- Improved power management by controlling power flow to specific devices, reducing energy waste.

- Reduced downtime through remote rebooting, minimizing disruptions.

- Enhanced reliability by quickly addressing issues to ensure uninterrupted operations.

- Integration with power management software provides detailed energy usage insights.

Power strips do not support individual outlet control. Their single switch affects all connected devices at once, offering no flexibility for targeted management. In critical IT settings, the ability to manage outlets individually helps maintain uptime, optimize energy use, and respond swiftly to issues.

Tip: For organizations that value operational efficiency and rapid response, choosing a solution with individual outlet control can make a measurable difference in reliability and energy savings.

PDU vs. Power Strip: Physical and Electrical Differences

Outlet Quantity and Types

Outlet configuration plays a crucial role in determining the suitability of a power distribution device for different environments. Power strips typically offer between 2 and 8 outlets, all of which are usually of the same type. This uniformity works well for home and small office setups, where users connect standard devices like computers, lamps, or chargers. In contrast, PDUs provide a much broader range, supporting anywhere from 4 to 48 outlets. These outlets can include a mix of types, such as IEC C13, C19, or country-specific sockets, tailored for diverse equipment needs in complex environments.

| Feature/Aspect | Power Strips | PDUs (Power Distribution Units) |

|---|---|---|

| Number of Outlets | 2–8, uniform type | 4–48, can include mixed types |

| Outlet Types | Usually uniform | Mixed types for various applications |

| Application Suitability | Home, small business | Industrial, enterprise, data centers |

| Additional Features | Surge protection options | Remote management, monitoring, device reboot |

| Use Case | Basic power needs | Advanced power management |

A PDU’s flexibility in outlet quantity and type makes it ideal for environments where equipment varies in power requirements and plug standards.

Inlet Types and Cordset Thickness

The inlet type and cordset thickness directly impact the safety and performance of power distribution devices. Power strips generally feature a single, country-specific inlet and a cordset with a thickness of 14 AWG, suitable for medium-duty appliances. This design limits their use to standard residential or office equipment.

PDUs, however, support both domestic and international-grade inlets, such as IEC 60309 or IEC C13/C19. Their cordsets range from 14 AWG up to 6 AWG, allowing them to safely handle higher electrical loads. Thicker cords reduce electrical resistance and heat buildup, which enhances safety and reliability in demanding environments.

| Aspect | PDUs | Power Strips |

|---|---|---|

| Inlet Types | Domestic and international-grade | Country-specific |

| Cordset Thickness | 14 AWG to 6 AWG, supports heavy loads | 14 AWG, suitable for medium-duty |

| Safety Features | Industrial-grade overload protection | Basic surge protection |

A thicker cordset and versatile inlet options enable a PDU to deliver power safely to a wide range of devices, reducing risks such as electrical shocks or overloads.

Power Phase and Voltage Support

Power phase and voltage support distinguish PDUs from power strips in terms of scalability and application. Power strips operate on single-phase power, supporting voltages up to 230 volts. This limitation makes them suitable for home offices and small-scale setups with minimal power demands.

PDUs offer both single-phase and three-phase options. Single-phase PDUs handle up to 230 volts, while three-phase models support up to 415 volts. Three-phase PDUs distribute power more efficiently, balance electrical loads, and support higher power capacities. These features make them essential for data centers, industrial facilities, and enterprise IT environments.

| Aspect | Single-Phase PDUs | Three-Phase PDUs |

|---|---|---|

| Voltage Range | Up to 230 volts | Up to 415 volts |

| Power Capacity | Suitable for smaller setups | High-demand environments |

| Power Distribution | Single AC waveform | Three AC waveforms, balanced load |

| Efficiency | Less efficient | More efficient, reduces energy loss |

| Typical Use Cases | Home offices, small setups | Data centers, industrial facilities |

| Scalability | Limited | High scalability |

Tip: For organizations planning future growth or managing high-density equipment, three-phase PDUs offer superior efficiency and scalability compared to standard power strips.

Mounting Options and Form Factor

Mounting options and form factor play a crucial role in selecting the right power distribution device for any environment. These features determine how easily users can install, access, and manage their power solutions.

PDUs: Flexible Mounting for Professional Environments

PDUs offer a wide range of mounting options. Manufacturers design them for integration into server racks, cabinets, and industrial enclosures. The most common mounting styles include:

- Vertical (0U) Mounting:

Technicians often install vertical PDUs along the side of server racks. This method saves valuable rack space for IT equipment. Vertical PDUs can support up to 48 outlets, making them ideal for high-density environments. - Horizontal (1U/2U) Mounting:

Horizontal PDUs fit into standard rack units, typically occupying 1U or 2U of rack space. This configuration works well for smaller setups or when vertical space is limited. - Wall or Surface Mounting:

Some PDUs feature brackets or flanges for secure attachment to walls, workbenches, or inside industrial cabinets. This flexibility supports custom installations in manufacturing or laboratory settings. - Floor-Mount and Free-Standing Options:

Heavy-duty PDUs sometimes come as free-standing units for large-scale industrial applications.

Power Strips: Simple and Portable Designs

Power strips focus on convenience and portability. Their mounting options remain limited compared to PDUs. Common approaches include:

- Desktop Placement:

Most users place power strips directly on desks, floors, or countertops. The compact form factor makes them easy to move as needed. - Keyhole Slots or Adhesive Pads:

Some power strips include keyhole slots for wall mounting or adhesive pads for temporary attachment to surfaces. These features suit home offices or entertainment centers. - Under-Desk Mounting:

Select models offer brackets for mounting under desks, keeping cords organized and out of sight.

| Feature | PDUs | Power Strips |

|---|---|---|

| Rack Mounting | Vertical (0U), Horizontal (1U/2U) | Not supported |

| Wall/Surface Mounting | Yes, with brackets/flanges | Limited (keyhole slots/adhesive) |

| Floor/Free-Standing | Available for industrial models | Not typical |

| Desktop/Portable Use | Rare | Standard |

| Outlet Orientation | Customizable (front, rear, mixed) | Usually single row |

Tip: For data centers or server rooms, vertical rack-mounted PDUs maximize space and simplify cable management. In contrast, power strips work best for temporary setups or where portability matters.

Form factor also affects usability. PDUs feature robust steel or aluminum housings, supporting high outlet counts and heavy-duty use. Their elongated shapes fit seamlessly into racks or along walls. Power strips use lightweight plastic casings, with a compact rectangular design that fits easily in small spaces.

Selecting the right mounting option and form factor ensures safe, efficient, and organized power distribution for any application.

Application Scenarios for PDUs and Power Strips

Home and Office Environments

Selecting the right power distribution device depends on the environment and the complexity of the electrical needs. In homes and small offices, power strips often provide a practical solution. They offer affordability, ease of installation, and a compact design. Users can quickly connect computers, printers, or entertainment systems without specialized knowledge. Temporary setups, such as event booths or short-term workstations, also benefit from power strips due to their plug-and-play nature.

However, when a small office experiences higher power demands or plans for future expansion, entry-level PDUs become a better choice. These devices deliver enhanced safety and improved load management. They prepare the workspace for additional equipment and help prevent overloads. The table below summarizes recommended scenarios:

| Environment/Scenario | Recommended Device | Key Reasons/Features |

|---|---|---|

| Small Offices | Power Strips | Affordable, easy to install, suitable for basic power needs like computers and printers. |

| Home Users on Budget | Power Strips | Cost-effective, simple plug-and-play design, compact size. |

| Temporary Setups | Power Strips | Suitable for short-term use, minimal power demands, easy to deploy. |

| Data Centers & Server Rooms | PDUs | Advanced features: remote monitoring, outlet-level control, scalability, robust safety mechanisms. |

| High-Demand Small Offices | Entry-level PDUs | Enhanced safety, better load management, future expansion readiness. |

Tip: For basic needs, power strips suffice. For growing offices or critical equipment, consider upgrading to a PDU for added safety and scalability.

Data Centers and Server Rooms

Data centers and server rooms require advanced power management. These environments house sensitive and high-value equipment. PDUs play a central role in delivering safe, reliable, and scalable power. Certified personnel should handle installation and maintenance to ensure compliance with safety standards. Strict procedures, such as careful inspection of connections and insulation resistance testing, help prevent electrical hazards.

Best practices for deploying PDUs in these settings include:

- Certified personnel must perform installation and maintenance.

- Inspect and secure all electrical connections, focusing on protective earth cables.

- Test insulation resistance to confirm safety thresholds.

- Conduct no-load and load tests to verify operational reliability.

- Follow safety rules: disconnect power during maintenance, secure installations, and shield live components.

Technicians can use remote activators to add circuits or power equipment from outside hazardous zones, reducing the need for personal protective equipment. Intelligent PDUs with remote management and environmental sensors allow real-time monitoring of power usage, temperature, and humidity. Access control and video surveillance protect unstaffed or edge data centers. Environmental monitoring detects heat buildup or leaks, preventing equipment damage.

Industrial and Commercial Settings

Industrial and commercial environments present unique challenges for power distribution. Operators must assess total load, phase balance, and future growth to select the right device. Environmental factors, such as temperature and humidity, influence the choice. PDUs rated for high temperatures or moisture protection ensure safe operation.

Scalability and flexibility matter in these settings. Modular PDUs allow easy expansion and reconfiguration. Advanced features, such as remote monitoring and network connectivity, support centralized management. Environmental sensors track temperature, humidity, and airflow, helping prevent equipment failure.

Device selection depends on application complexity. Basic power strips or PDUs work for small or less critical setups. Larger or mission-critical environments benefit from advanced PDUs that offer metering, monitoring, and remote management.

Note: Careful planning and the right device selection protect equipment, support growth, and maintain safe operations in demanding environments.

Safety Considerations for Power Distribution

Electrical Load Management

Effective electrical load management ensures safe and reliable operation of PDUs and power strips. Facility managers must distribute power connections evenly across all circuits to prevent overload and maintain redundancy. They should keep the current load below 80% of the device’s rated capacity. Monitoring peak load history helps identify patterns and avoid unexpected surges. Proper cable management, such as routing cords neatly and securing them with ties, maintains airflow and reduces tension on connections. Environmental conditions play a critical role. Maintaining ambient temperature and humidity within recommended ranges—typically 40-60% humidity—protects equipment from moisture and overheating. Regular inspections and testing, including monthly visual checks and annual infrared scans, help detect wear or damage early. Intelligent PDUs provide real-time monitoring, allowing staff to verify phase balance and track environmental changes.

| Aspect | Best Practices & Guidelines |

|---|---|

| Load Balancing | Distribute power evenly across PDUs and circuits to avoid overload and ensure redundancy. |

| Load Management | Keep current load below 80% of capacity; monitor peak load history. |

| Cable Management | Organize power cords; avoid tension; maintain airflow; use cable ties or management systems. |

| Environmental Conditions | Maintain temperature and humidity within specifications; ensure adequate airflow and physical protection. |

| Inspection & Testing | Perform monthly inspections; check load levels and temperature; conduct annual scans and firmware updates. |

| Monitoring | Use intelligent PDUs for real-time monitoring; verify phase balance on three-phase PDUs. |

Tip: Regular maintenance and monitoring reduce the risk of electrical faults and extend equipment lifespan.

Risk of Overloading

Overloading remains a leading cause of electrical failures and fire hazards in both PDUs and power strips. Users often create overloads by plugging in too many high-power devices, such as space heaters, toasters, or crockpots. These appliances draw significant current and can quickly exceed the device’s rated capacity. Daisy-chaining power strips—connecting one strip into another—poses a severe risk and violates safety regulations. This practice increases the chance of overheating and electrical fires. Prevention starts with limiting high-power appliances to one per power strip. Users should avoid placing power strips under rugs or in enclosed spaces, as these conditions trap heat and increase fire risk. Damp areas also present hazards, especially near children, who may insert objects into outlets. Never exceed the total rated capacity of a power strip or PDU, regardless of the number of available outlets.

Common causes and prevention strategies include:

- Plugging in multiple high-power devices, especially heating appliances.

- Daisy-chaining power strips, which increases fire and failure risks.

- Limiting high-power appliances to one per power strip.

- Avoiding placement under rugs or in enclosed spaces to prevent heat buildup.

- Keeping power strips away from damp areas and children.

- Ensuring total device load does not exceed rated capacity.

Note: Proper load assessment and safe usage practices prevent overloading and protect both equipment and personnel.

Fire Hazards and Prevention

Improper use of PDUs and power strips can lead to fire hazards. Daisy-chaining power strips remains one of the most dangerous practices, often resulting in overheating and violating workplace safety standards. Placing power strips under rugs or in tightly enclosed spaces restricts airflow, causing heat buildup and increasing the risk of fire. Physical damage to cords, such as fraying or crushing, can expose wires and create shock or fire risks. Children should not have access to power strips, as inserting objects into outlets may result in accidents. Damp environments, including basements or areas with sump pumps, require special attention. Ground Fault Circuit Interrupter (GFCI) outlets installed above floor level offer safer alternatives. Overloading power strips with multiple high-power appliances, such as heaters or toasters, should be avoided. Limiting these devices to one per strip prevents overheating and reduces fire risk.

Recommended fire prevention measures:

- Avoid daisy-chaining power strips.

- Do not place power strips under rugs or in enclosed spaces.

- Keep power strips away from children.

- Use GFCI outlets in damp areas instead of power strips.

- Limit high-power appliances to one per strip.

⚠️ Always follow manufacturer guidelines and safety standards to minimize fire hazards and ensure safe power distribution.

Compliance with Safety Standards

Compliance with safety standards stands as a critical factor in power distribution. PDUs and power strips must meet strict guidelines to ensure user safety and equipment protection. Manufacturers design these devices to pass rigorous tests set by recognized organizations. These standards help prevent electrical hazards, reduce fire risks, and guarantee reliable operation.

Key Safety Certifications and Standards

| Certification/Standard | Description | Commonly Applies To |

|---|---|---|

| UL (Underwriters Laboratories) | Verifies electrical safety and fire resistance | PDUs, Power Strips |

| CE (Conformité Européenne) | Confirms compliance with European safety laws | PDUs, Power Strips (Europe) |

| RoHS (Restriction of Hazardous Substances) | Limits hazardous materials in electronics | Both |

| CSA (Canadian Standards Association) | Ensures safety for Canadian markets | Both |

| ISO9001 | Certifies quality management systems | Manufacturing Process |

| VDE (Verband der Elektrotechnik) | German electrical safety certification | Both |

Tip: Always check for certification labels on the device or packaging. These marks indicate that the product has passed independent safety testing.

Why Compliance Matters

- Reduces Fire Hazards: Certified devices use flame-retardant materials and undergo fire resistance tests.

- Prevents Electrical Shock: Standards require proper insulation, grounding, and protective earth connections.

- Ensures Reliable Performance: Certified products maintain consistent operation under rated loads and environmental conditions.

- Supports Legal and Insurance Requirements: Many workplaces and insurance policies mandate the use of certified equipment.

Best Practices for Ensuring Compliance

- Inspect devices for visible certification marks such as UL, CE, or CSA.

- Review the manufacturer’s documentation for compliance details.

- Purchase from reputable suppliers who provide proof of certification.

- Replace damaged or uncertified power strips and PDUs immediately.

- Train staff to recognize and report non-compliant equipment.

⚠️ Non-compliant devices may pose serious risks, including electrical fires, equipment failure, or injury. Facilities should never use uncertified power strips or PDUs in critical environments.

Summary Table: Safety Compliance Checklist

| Action Item | Why It Matters |

|---|---|

| Verify certification labels | Confirms product safety |

| Review documentation | Ensures compliance with standards |

| Buy from trusted suppliers | Reduces risk of counterfeit devices |

| Replace damaged equipment | Maintains safety and reliability |

| Train staff on compliance | Promotes a culture of safety |

Compliance with safety standards protects people, property, and equipment. Organizations that prioritize certified PDUs and power strips create safer, more reliable environments for everyone.

How to Choose: PDU or Power Strip?

Selecting the right power distribution device requires careful evaluation of the environment, power needs, and safety priorities. The following guide helps users make informed decisions for both simple and complex setups.

Assessing Your Environment

Home and Small Office

Home users and small office managers often need a straightforward solution for powering computers, printers, and entertainment systems. Power strips provide a practical choice in these settings. Their compact design and easy installation suit desks, entertainment centers, and kitchen counters. Most users do not require advanced monitoring or remote management in these environments.

Tip: For basic electronics and appliances, a power strip offers convenience and affordability.

Professional and Industrial Settings

Professional and industrial environments demand higher safety standards and greater flexibility. Data centers, laboratories, and manufacturing floors often house sensitive or high-powered equipment. In these cases, a PDU delivers robust protection, advanced monitoring, and support for multiple device types. Facilities with rack-mounted servers or network switches benefit from the scalability and control that a PDU provides.

Evaluating Power Needs

Number of Devices

Users should count the number of devices that require power. Power strips typically support up to eight outlets, which works well for home or small office use. Larger setups, such as server racks or industrial workstations, may need 12, 24, or even 48 outlets. A PDU accommodates these higher outlet counts and offers a variety of outlet types for different equipment.

Power Consumption

Understanding the total power consumption of connected devices prevents overloads and ensures safe operation. Users should check the wattage or amperage ratings of each device. Power strips handle moderate loads, while a PDU supports higher current and voltage levels. Facilities with power-hungry equipment, such as servers or industrial machines, should select a device rated for their maximum load.

| Device Type | Typical Outlet Count | Max Supported Load |

|---|---|---|

| Power Strip | 2–8 | Up to 15A/1800W |

| PDU | 4–48 | Up to 60A/14kW+ |

Prioritizing Safety Features

Surge Protection

Surge protection remains essential for safeguarding electronics from voltage spikes. Most power strips include basic surge suppressors, which protect home and office devices. In contrast, professional environments may require industrial-grade surge protection, available in advanced PDUs.

Monitoring Capabilities

Monitoring features help users track power usage and detect potential hazards. Intelligent PDUs offer real-time monitoring, alerts, and remote access. These capabilities prove valuable in data centers and industrial sites, where downtime or equipment failure can have serious consequences. Power strips rarely provide monitoring, making them less suitable for critical applications.

Note: Prioritizing safety features such as surge protection and monitoring ensures long-term reliability and peace of mind.

Budget and Long-Term Value

When evaluating power distribution solutions, organizations and individuals must consider both the initial purchase price and the total cost of ownership. Power strips usually attract buyers with their low upfront cost. Most basic models cost between $10 and $40. Even surge-protected or smart power strips rarely exceed $60. This affordability makes power strips a popular choice for home users and small offices with limited budgets.

PDUs, on the other hand, require a higher initial investment. Basic PDUs start around $60, while advanced models—such as metered, switched, or intelligent PDUs—can range from $150 to over $1,000. The price reflects the robust construction, advanced safety features, and monitoring capabilities that PDUs provide.

| Device Type | Typical Price Range | Expected Lifespan | Maintenance Needs | Upgrade Potential |

|---|---|---|---|---|

| Power Strip | $10–$60 | 2–5 years | Low | Limited |

| Basic PDU | $60–$200 | 5–10 years | Low | Moderate |

| Advanced/Smart PDU | $150–$1,000+ | 8–15 years | Moderate | High |

Tip: Investing in a higher-quality device often reduces replacement frequency and lowers the risk of costly equipment damage.

Durability plays a significant role in long-term value. Power strips, built with plastic housings and lighter cordsets, may wear out faster, especially in demanding environments. Frequent plugging and unplugging, exposure to heat, or accidental drops can shorten their lifespan. PDUs, constructed with steel or aluminum and thicker cables, withstand harsh conditions and heavy use. Many PDUs also offer replaceable components, which extends their service life.

Maintenance and upgrade potential further influence total cost. Power strips offer limited options for repair or expansion. When a power strip fails, users typically replace the entire unit. PDUs, especially intelligent models, support firmware updates, modular upgrades, and component replacement. These features help organizations adapt to changing needs without frequent full replacements.

Long-term value also includes indirect savings. PDUs with monitoring and alert features help prevent overloads and downtime. By reducing the risk of equipment failure or fire, these devices protect valuable assets and minimize costly disruptions. In environments where uptime and safety matter, the higher upfront cost of a PDU often pays off over time.

Organizations that prioritize reliability and safety should view PDUs as an investment, not just an expense. Over several years, the reduced maintenance, longer lifespan, and enhanced protection can deliver significant savings.

Choosing between a power strip and a PDU involves more than comparing price tags. Buyers should weigh durability, upgrade options, and the potential for long-term savings. A thoughtful investment today can prevent expensive problems tomorrow.

Real-World Examples and Recommendations

When to Use a PDU

IT managers often select a PDU for environments that demand high reliability and advanced control. Data centers, server rooms, and industrial automation lines require precise power management. For example, a financial institution may deploy a PDU in its server racks to monitor energy consumption and prevent overloads. Hospitals use PDUs to ensure continuous operation of life-support equipment. Manufacturing plants rely on PDUs to distribute three-phase power to heavy machinery. These scenarios benefit from features such as remote monitoring, individual outlet control, and robust overload protection.

Tip: Choose a PDU when the environment involves mission-critical equipment, high power density, or the need for remote management.

When a Power Strip Is Sufficient

Power strips work well in homes, classrooms, and small offices. A teacher might use a power strip to connect a projector, laptop, and speakers in a classroom. Homeowners often use power strips for entertainment centers, lamps, or kitchen appliances. Small businesses can power computers and printers at workstations with a basic power strip. These devices provide a cost-effective solution for low to moderate power needs. Surge-protected models add an extra layer of safety for sensitive electronics.

| Scenario | Recommended Device | Reason |

|---|---|---|

| Home entertainment | Power Strip | Simple, affordable, easy to use |

| Classroom electronics | Power Strip | Portable, supports multiple devices |

| Small office workstations | Power Strip | Sufficient for basic equipment |

Common Mistakes to Avoid

Many users make errors that compromise safety and equipment longevity. Daisy-chaining power strips—plugging one into another—creates a serious fire hazard. Overloading a power strip by connecting too many high-wattage devices can cause overheating. Placing power strips under rugs or in damp areas increases the risk of electrical shock and fire. Failing to check the total load before plugging in devices often leads to tripped breakers or damaged equipment. Ignoring certification labels may result in using non-compliant products that lack essential safety features.

⚠️ Always follow manufacturer guidelines, avoid daisy-chaining, and check for safety certifications before use.

Quick-Reference Comparison Table

Selecting the right power distribution device can feel overwhelming. This quick-reference table highlights the most important differences between PDUs (Power Distribution Units) and power strips. Facility managers, IT professionals, and even home users can use this table to make informed decisions for safer and more efficient power management.

| Feature / Aspect | PDU (Power Distribution Unit) | Power Strip |

|---|---|---|

| Typical Use | Data centers, server rooms, industrial, commercial | Homes, small offices, classrooms |

| Outlet Quantity | 4–48 (varied types: IEC C13, C19, Schuko, etc.) | 2–8 (usually uniform, country-specific) |

| Inlet Types | Domestic and industrial (IEC 60309, NEMA L6-30P, etc.) | Single domestic (NEMA 5-15P, BS1363, etc.) |

| Cordset Thickness | 14 AWG to 6 AWG (supports higher current) | 14 AWG (medium-duty) |

| Voltage & Phase Support | Single-phase (110V/208V/230V) and three-phase (208V/400V) | Single-phase only (110V/208V/230V) |

| Mounting Options | Rack-mount (vertical 0U, horizontal 1U/2U), wall, floor, cabinet | Desktop, under-desk, wall (limited) |

| Build Quality | Steel or aluminum chassis, flame-retardant components | Plastic housing, basic flame resistance |

| Overload Protection | Industrial-grade circuit breakers, resettable fuses, MCBs | Basic fuses or circuit breakers (if present) |

| Surge Protection | Available in some models, often advanced | Common in many models, basic level |

| Monitoring & Alerts | Advanced: real-time monitoring, remote alerts, event logging | Rare, limited to some smart strips |

| Individual Outlet Control | Available in switched/intelligent models | Not available |

| Remote Management | Yes (network, wireless, SNMP, web interface) | No |

| Durability & Lifespan | 5–15 years (heavy-duty, replaceable parts) | 2–5 years (light-duty, replace entire unit) |

| Compliance & Certification | UL, CE, RoHS, CSA, VDE, ISO9001 | UL, CE, RoHS, CSA (varies by model) |

| Price Range | $60–$1,000+ | $10–$60 |

Tip:

For environments with critical equipment or high power demands, a PDU offers advanced safety, monitoring, and control. For basic home or office needs, a power strip provides a simple and cost-effective solution.

Key Takeaways:

- PDUs deliver robust safety, scalability, and control for professional environments.

- Power strips suit everyday use where power needs remain modest.

- Always check for safety certifications before purchase.

- Never exceed the rated load of any device.

Checklist for Choosing:

- Assess the number and type of devices.

- Consider the environment (home, office, data center).

- Prioritize safety features and monitoring needs.

- Factor in long-term durability and upgrade potential.

Choosing the right device protects your equipment, reduces fire risk, and ensures reliable power distribution.

PDUs and power strips differ in safety features, outlet capacity, and monitoring capabilities. PDUs suit data centers and industrial spaces, offering advanced protection and control. Power strips work best for homes and small offices with basic needs.

- PDUs: Ideal for high-demand, mission-critical environments

- Power strips: Practical for everyday electronics

Tip: Always check device certifications and match the power solution to the environment. Choosing wisely protects equipment and ensures safe, reliable power distribution.

FAQ

What is the main safety difference between a PDU and a power strip?

A PDU uses industrial-grade components, such as circuit breakers and resettable fuses, to prevent overloads. Power strips usually offer only basic surge protection. PDUs provide higher safety for critical environments.

Can you daisy-chain power strips or PDUs?

Electrical safety experts advise against daisy-chaining power strips or PDUs. This practice increases the risk of overheating and fire. Always connect devices directly to a wall outlet or a single certified power distribution unit.

How do you know if a PDU or power strip is certified for safety?

Look for certification labels such as UL, CE, or CSA on the device or packaging. Certified products meet strict safety standards. Always check documentation before purchase.

When should someone choose a PDU over a power strip?

Select a PDU for data centers, server rooms, or industrial sites with high power demands. PDUs offer advanced monitoring, remote management, and support for more devices. Power strips suit basic home or office needs.

Do all power strips provide surge protection?

Not all power strips include surge protection. Basic models only expand outlet capacity. Surge-protected models shield electronics from voltage spikes. Always check product specifications before use.

What is the lifespan of a typical PDU or power strip?

A PDU often lasts 5 to 15 years due to its robust construction. Power strips usually last 2 to 5 years. Lifespan depends on usage, environment, and build quality.

Can PDUs be used in residential settings?

PDUs can serve residential environments with high power needs or specialized equipment. However, most homes benefit from power strips due to their simplicity and lower cost.

How many devices can you safely connect to a power strip or PDU?

Power strips support 2 to 8 devices, while PDUs handle 4 to 48 devices. Always check the device’s rated capacity and avoid exceeding the maximum load to ensure safe operation.

Post time: Aug-11-2025