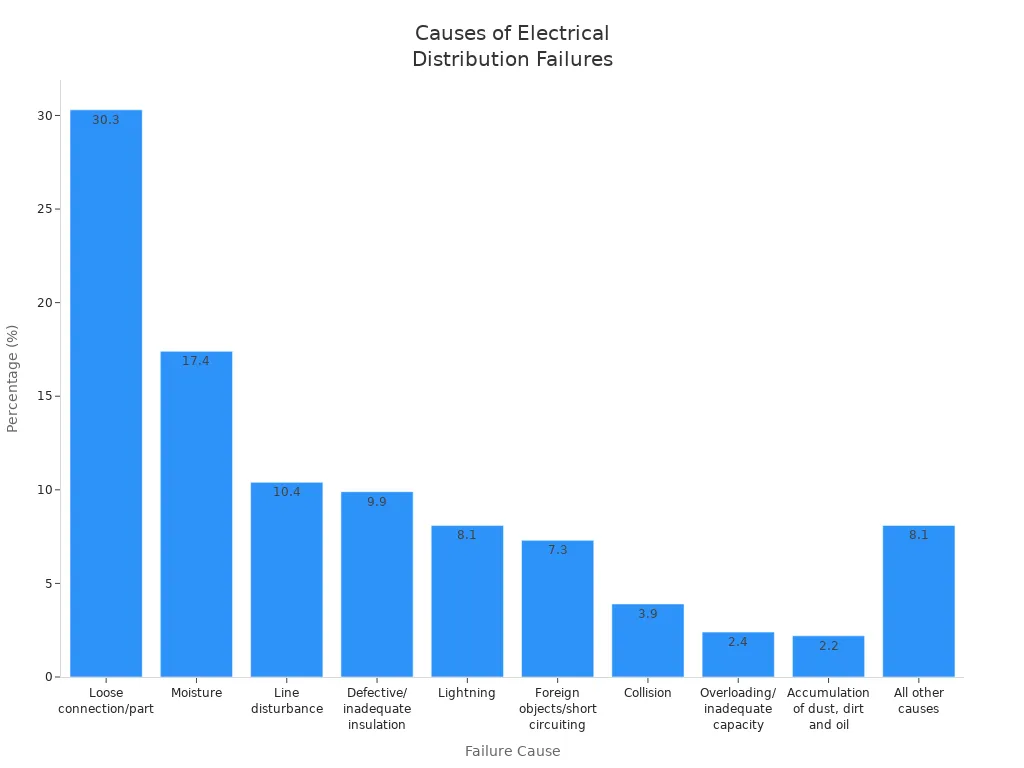

Regular cleaning of a basic PDU prevents dust buildup that can lead to overheating and power issues. Even though only 2.2% of failures result from dust, this small percentage still threatens uptime.

Technicians often compare maintenance needs between a basic PDU and an intelligent PDU to ensure equipment longevity.

Key Takeaways

- Check and clean your Basic PDU every three to six months to prevent dust buildup and avoid power failures.

- Always disconnect power and use proper tools and safety gear before inspecting or cleaning to stay safe.

- Perform visual inspections, clean dust with microfiber cloths, and test outlets after cleaning to keep your PDU working well.

Basic PDU: What, Why, and When

What Is a Basic PDU?

A Basic PDU serves as a heavy-duty power strip designed for data centers, server rooms, and office environments. It distributes power from a single input source to multiple output outlets. Unlike intelligent PDUs, a Basic PDU does not offer monitoring or remote control features. Its main purpose is to supply power to several devices within a rack, such as servers, routers, switches, and telecommunications equipment. Many small businesses and offices choose a Basic PDU for its simplicity and cost-effectiveness.

- Distributes alternating current (AC) to multiple devices

- Organizes power delivery on a per-rack basis

- Lacks advanced monitoring or control functions

- Commonly installed in environments that value straightforward power management

Why Regular Maintenance Is Important

Regular maintenance of a Basic PDU prevents unexpected power failures and equipment downtime. Dust buildup can impair performance and reduce energy efficiency. Environmental factors like humidity, temperature extremes, and vibration may damage electrical components. Without routine checks, overheating and worn parts can go unnoticed, increasing the risk of costly failures.

Preventive maintenance, including visual inspections and cleaning, helps identify issues early and ensures reliable operation.

When and How Often to Check and Clean

Technicians recommend inspecting and cleaning a Basic PDU every three to six months. High-traffic or dusty environments may require more frequent attention.

- Schedule regular visual inspections

- Clean outlets and surfaces to remove dust

- Check for signs of wear or overheating

- Adjust frequency based on environmental conditions

Basic PDU Maintenance and Troubleshooting Guide

Safety Precautions

Technicians must prioritize safety when maintaining or cleaning a Basic PDU. Electrical maintenance presents several hazards that can lead to injury or equipment damage.

- Damaged tools and equipment, such as cracked cords, which increase the risk of electric shock

- Overloaded circuits that may cause overheating or fire

- Exposure to overhead power lines, which can result in electrocution or burns

- Exposed electrical parts and damaged insulation, both of which can cause shocks or burns

- Improper grounding, which raises the risk of electrocution

- Wet conditions, which make electrical work especially dangerous

Before starting any work, always disconnect the power supply. Inspect all tools for damage and replace any with cuts or exposed wires. Ensure the work area is dry and free from clutter. Maintain a safe distance from overhead power lines and never attempt temporary fixes with tape on damaged insulation. Proper grounding remains essential for safe operation.

Tools and Supplies Needed

A well-prepared technician gathers all necessary tools and supplies before beginning maintenance. The following list covers the essentials for Basic PDU care:

- Insulated screwdrivers and pliers

- Flashlight for detailed inspection

- Microfiber cloths for dust removal

- Prepackaged disinfectant wipes (containing accelerated hydrogen peroxide or quaternary ammonium compounds)

- Voltage tester or multimeter

- Personal protective equipment (PPE) such as gloves and safety glasses

- Cable ties for securing loose wires

- Camera or smartphone for documenting issues

Using the correct tools reduces the risk of accidents and ensures a thorough, efficient maintenance process.

Visual Inspection Steps

A careful visual inspection helps identify early warning signs of Basic PDU failure. Technicians should follow these steps:

- Use a flashlight to inspect all areas of the PDU for better visibility.

- Look for discoloration on the housing or outlets, which may indicate overheating.

- Check for burn marks or signs of arcing on outlets and connections.

- Inspect for physical damage, such as cracks, loose components, or unauthorized modifications.

- Document any damage or anomalies with photos for maintenance records.

- Ensure the housing is intact, mounting brackets are secure, and there is no dust or debris accumulation.

- Verify that outlets are not loose, wobbly, or showing signs of melting or burning.

- Confirm that unused outlets have protective covers if available.

Periodic inspections should focus on evidence of overheating, dust buildup, and connection integrity. These steps help detect problems before they escalate into failures.

Cleaning the Basic PDU

Proper cleaning extends the life of a Basic PDU and maintains optimal performance. Follow this step-by-step procedure:

- Turn off the power to the PDU before starting any cleaning or maintenance.

- Use only insulated tools to prevent electric shocks.

- Ensure the cleaning area is dry and free from clutter.

- Remove dust using a dry microfiber cloth, which minimizes dust dispersion and is effective at removing microbes.

- For more thorough cleaning, use prepackaged disinfectant wipes with accelerated hydrogen peroxide or quaternary ammonium compounds. Follow manufacturer instructions for dilution, contact time, rinsing, and drying.

- Avoid blocking airflow or other equipment during cleaning.

- Secure all cables to prevent tripping or accidental disconnection.

- After cleaning, allow all surfaces to dry thoroughly before restoring power.

Tip: Remove organic material before disinfection, rinse after using detergent, and always wear appropriate PPE during cleaning.

Testing After Cleaning

Testing after cleaning ensures the Basic PDU functions safely and reliably. Technicians should perform the following tests:

- Check the circuit breaker response by simulating an overcurrent event to ensure breakers trip as expected.

- Monitor power metrics such as voltage, current, and power consumption to verify proper delivery.

- Inspect each outlet to confirm consistent power supply.

- Use waveform analysis to capture power events and identify irregularities.

- Test circuit breakers by simulating overload conditions.

- Verify electrical connections with a multimeter for continuity and correct voltage.

Comprehensive post-cleaning testing detects potential faults or residual contamination. This process helps maintain operational integrity and prevents future power distribution issues.

Troubleshooting Checklist

A structured troubleshooting checklist enables technicians to resolve Basic PDU issues quickly and efficiently:

- If overload protection activates frequently, check and redistribute the power load to prevent overload.

- For unresponsive outlets, inspect circuit breakers and wiring, reset breakers, and verify all connections.

- If monitoring reports are inaccurate, update firmware and calibrate sensors if applicable.

- Document all issues and repairs in maintenance logs for future reference.

Troubleshooting checklists serve as quick reference tools during emergencies, helping staff identify and resolve common problems. Regular inspections, preventive maintenance, and proper documentation significantly reduce downtime and improve reliability.

Regular inspection and cleaning of a Basic PDU help prevent equipment failure and extend asset lifespan. Organizations that follow a maintenance schedule see fewer breakdowns, lower repair costs, and improved reliability. A simple routine keeps power distribution safe and efficient, supporting long-term operational success.

FAQ

How often should technicians clean a basic PDU?

Technicians should clean a basic PDU every three to six months. Dusty or high-traffic environments may require more frequent cleaning to maintain optimal performance.

What signs indicate a basic PDU needs maintenance?

Discoloration, burn marks, loose outlets, or unusual noises signal maintenance needs. Technicians should also check for dust buildup and overheating during routine inspections.

Can users clean a basic PDU while it is powered on?

Never clean a basic PDU while powered on. Always disconnect the power supply before starting any cleaning or maintenance to ensure safety.

Post time: Jul-10-2025