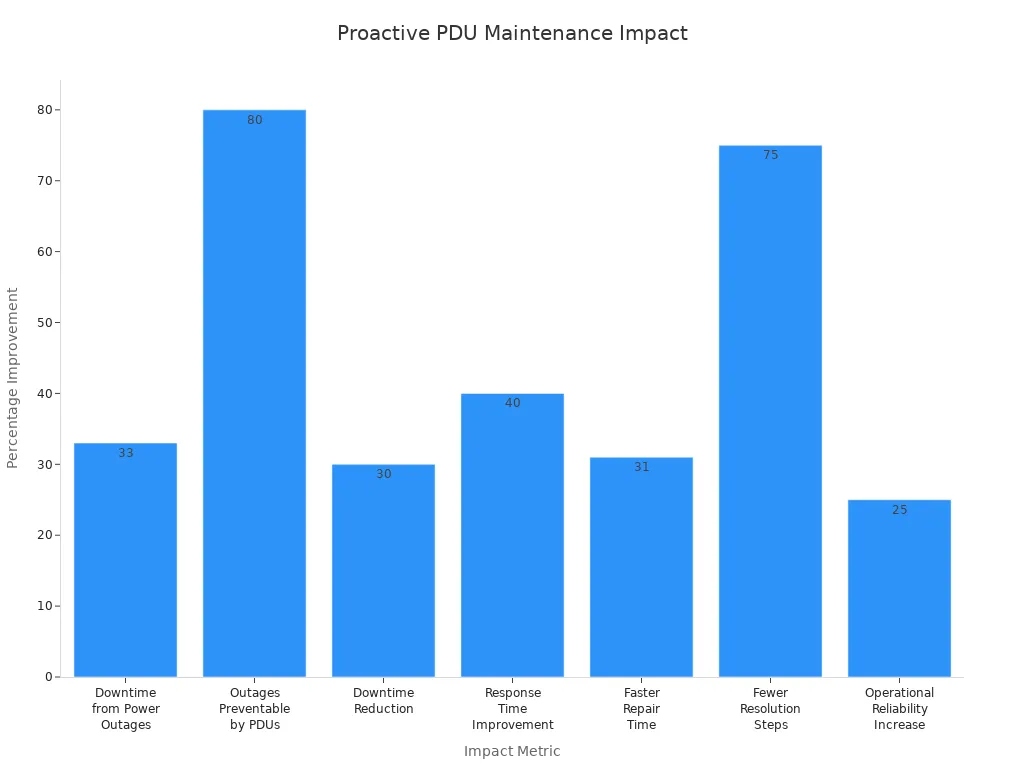

Reliable power distribution plays a crucial role in supporting data center and telecom operations. Facilities that implement proactive PDU maintenance see a 30% drop in downtime incidents, as shown below:

By using a Basic PDU for essential circuits and monitoring power loads, organizations can prevent costly disruptions and improve uptime.

Key Takeaways

- Regularly inspect and maintain PDUs to catch problems early and extend equipment life.

- Use intelligent PDUs with real-time monitoring and remote control to prevent overloads and quickly fix issues.

- Train staff well and practice response plans to reduce errors and handle emergencies effectively.

PDU Inspection and Preventive Maintenance

Scheduled Visual Inspections

Routine visual inspections form the foundation of effective PDU maintenance. Technicians examine hardware, switches, circuit breakers, displays, and bulbs for signs of wear or damage. Cleaning dust and debris from components helps maintain energy efficiency and prevents environmental factors from causing harm. Facilities that schedule regular inspections reduce the risk of unexpected failures and extend equipment lifespan.

Testing and Verifying PDU Connections

Testing and verifying electrical connections ensures safe and reliable operation. Qualified personnel perform these tests on de-energized equipment, following industry standards such as NETA Acceptance and Maintenance Testing Specifications. The table below outlines common procedures:

| PDU Component | Tests / Procedures | Notes / Standards Referenced |

|---|---|---|

| Circuit Breakers | Trip unit injection, contact resistance | Ensures reliability and safety |

| Isolation Transformer | Polarization Index, winding resistance | Transformer-specific tests |

| PDU Bus | Connection resistance, insulation resistance | Ensures proper bus connections |

| Grounding | 2-point continuity check | Verifies grounding integrity |

| Metering | Voltage/current injection | Confirms metering precision |

Modern facilities also use IIOT-based infrared sensors for real-time temperature monitoring, which improves fault detection rates and enhances personnel safety.

Replacing Worn or Faulty PDU Components

Technicians identify and replace worn or faulty components by following a structured process:

- Inspect all parts for wear or damage.

- Clean and de-energize before maintenance.

- Check calibration and functionality of monitoring devices.

- Document all activities and follow manufacturer guidelines.

- Employ qualified professionals for all replacements.

Maintaining Detailed Maintenance Logs

Comprehensive maintenance logs support reliability-centered strategies. These logs track inspection dates, work performed, personnel involved, equipment status, and calibration needs. Facilities use logs to analyze root causes of outages, collaborate with vendors, and ensure consistent standards. Logs should include real-time power metrics, environmental data, event histories, and service reports for complete documentation.

PDU Load Management and Balancing

Monitoring PDU Power Loads

Data center managers rely on intelligent PDUs and monitoring tools to track power loads in real time. Intelligent PDUs offer advanced metering and remote control, allowing operators to monitor power consumption at the outlet level. These devices send proactive notifications and support remote power cycling, which helps prevent overloads and inefficiencies. Tools like PRTG Network Monitor provide real-time visualization, customizable alerts, and detailed reporting for each connected PDU. Smart PDUs also integrate with centralized management software, enabling continuous tracking and optimization of energy usage.

Avoiding Overloads and Hotspots

Improper load management in high-density server environments can lead to serious consequences:

- Overloaded power sources may trip circuit breakers, cause overheating, and damage equipment.

- Misconfigured PDUs or ATS settings create single points of failure, negating redundancy.

- Lack of regular monitoring allows issues like fluctuating power or heat buildup to go undetected.

- Inadequate testing of PDUs and components can result in unexpected failures during transitions or overloads.

To prevent these risks, facilities should use intelligent PDUs with real-time monitoring, distribute high-power devices across multiple units, and maintain proper airflow. Temperature sensors and routine inspections help identify and address hotspots before they escalate.

Implementing Three-Phase Load Balancing

Three-phase load balancing improves efficiency and reliability by ensuring even power distribution across all phases. Unbalanced loads increase current flow between transformer legs, generating waste heat and raising cooling costs. Balanced loads reduce heat, lower cooling requirements, and improve Power Usage Effectiveness (PUE). Modern PDUs with alternating phase outlets simplify load balancing and cable management, making it easier to prevent overloading and maximize operational reliability.

Upgrading to Intelligent PDUs for Monitoring

Real-Time PDU Monitoring Capabilities

Intelligent PDUs provide real-time monitoring of power usage, voltage, and current at the outlet level. This capability allows data center teams to detect anomalies immediately and take action before issues escalate. Environmental sensors integrated into these units track temperature and humidity, helping prevent hotspots and equipment overheating. Real-time alerts based on user-defined thresholds enable staff to respond quickly to abnormal conditions. These features support predictive maintenance, reducing the risk of downtime and improving operational reliability.

Tip: Real-time monitoring helps identify underutilized servers, which can be consolidated or decommissioned to save energy and costs.

Remote Management and Automated Alerts

Remote management features in intelligent PDUs allow IT staff to control outlets, reboot devices, and monitor environmental factors from any location. Automated alerts notify administrators of sudden energy spikes or environmental changes, enabling rapid intervention. Remote power cycling eliminates the need for on-site visits, which speeds up troubleshooting and reduces downtime. In distributed or high-density environments, centralized management streamlines operations and ensures consistent power delivery.

- Managed PDUs enable:

- Immediate detection of power and environmental issues

- Quick response through remote outlet control

- Reduced maintenance response times by up to 40%

Data Logging and Trend Analysis

Intelligent PDUs continuously log power and environmental data, supporting detailed trend analysis. This information helps facilities plan capacity, optimize cooling, and balance loads more effectively. Trend analysis identifies patterns such as recurring overloads or inefficient power usage, guiding decisions on equipment upgrades or consolidation. Organizations report operational cost reductions of up to 30% and improved Power Usage Effectiveness (PUE) when using these insights. Enhanced data visibility also supports sustainability goals by reducing energy waste.

PDU Environmental and Physical Care

Ensuring Proper Ventilation for PDUs

Proper ventilation stands as a critical factor in maintaining equipment reliability. Electrical enclosures require effective airflow to prevent overheating, moisture buildup, and pressure issues. Heat generated by electrical components must dissipate efficiently. Facilities often use passive ventilation, such as vents and louvers, for basic airflow. In high-density environments, active systems like fans or blowers help force cool air through enclosures. Hybrid systems combine both methods for optimal cooling. Technicians also recommend perforated doors, organized cabling, and hot aisle/cold aisle layouts to enhance airflow. These strategies reduce the risk of thermal challenges, which have caused failures in data centers with poor airflow and insufficient temperature ratings.

Maintaining Cleanliness Around PDUs

Dust and debris pose significant threats to operational reliability. Accumulated particles can block airflow, leading to overheating and increased strain on cooling systems. This not only raises energy costs but also shortens equipment lifespan. Regular cleaning and inspections help maintain performance. Industry standards, such as ISO 14644, guide facilities in controlling contamination. Routine maintenance checks allow teams to spot and address dust buildup before it impacts equipment.

Using Surge Protection and Power Conditioning

Power spikes and surges can damage sensitive equipment and disrupt operations. Facilities protect critical systems by installing robust surge protection devices and advanced battery backup units. Regular inspections of wiring, grounding, and connections further reduce risks. Upgrading outdated infrastructure and integrating uninterruptible power supplies ensure continuous operation during outages. Commercial electrical contractors often design and maintain these systems for environments where uptime is essential.

PDU Staff Training and Response Protocols

Training Staff on PDU Best Practices

Effective staff training forms the backbone of reliable power management. Teams should follow a structured approach to ensure safe and efficient operations:

- Schedule regular maintenance and inspections to catch issues early.

- Monitor power usage to optimize performance and balance loads.

- Implement redundancy by using dual-corded equipment and dual input feeds.

- Use remote management tools for centralized monitoring and rapid troubleshooting.

- Maintain organized cable systems to improve airflow and reduce hazards.

- Update firmware regularly to enhance security and device functionality.

- Follow all relevant safety standards and regulations, such as NEC and IEC.

- Integrate environmental monitoring to track temperature and humidity.

Tip: Consistent training on these practices reduces human error and supports continuous uptime.

Establishing Incident Response Procedures

Every facility needs clear incident response procedures. Teams should document step-by-step actions for common scenarios, such as power loss or equipment failure. Quick reference guides and flowcharts help staff act decisively during emergencies. Assigning roles and responsibilities ensures that everyone knows their tasks. Regular reviews of these procedures keep them current and effective.

Conducting Regular Drills and Reviews

Routine drills prepare staff for real-world incidents. Simulated scenarios test response times and reveal gaps in protocols. After each drill, teams should review outcomes and update procedures as needed. This cycle of practice and feedback builds confidence and sharpens skills. Facilities that invest in regular training and reviews see faster recovery and fewer mistakes during actual events.

Consistent maintenance, real-time monitoring, and staff training reduce downtime and operational costs.

- A mid-sized data center saved $50,000 annually by adopting remote monitoring and advanced safety features.

- Leading companies report up to 50% lower costs and improved reliability after immediate implementation of best practices.

Proactive management supports long-term efficiency and sustainability.

FAQ

What is the recommended frequency for PDU inspections?

Technicians should inspect PDUs at least once every quarter. High-density environments may require monthly checks for optimal reliability.

How can staff identify early signs of PDU failure?

Staff should look for warning lights, unusual noises, or temperature spikes. Intelligent PDUs provide real-time alerts for abnormal conditions.

Do intelligent PDUs require special training for operation?

- Yes, staff must receive training on remote management, data analysis, and alert response to maximize the benefits of intelligent PDUs.

Post time: Jul-15-2025