Accidental power disconnections pose a significant threat to critical equipment. Lockable C13 and C19 outlets offer a vital solution. They prevent unexpected power loss. One study showed accidental or human error causes 24% of unplanned data center outages. Another survey found human error accounts for 51% of data center downtime. Such incidents carry high costs. Downtime can cost businesses $427 to $9,000 per minute. Implementing a 19”Lockable IEC C13 C19 rack power distribution unit or a 19”Lockable IEC C13 C19 rack pdu with these outlets ensures operational continuity. This applies to both a Basic PDU and an Intelligent PDU, safeguarding against costly interruptions.

Key Takeaways

- Lockable C13 and C19 outlets stop accidental power disconnections. They keep critical equipment running.

- These outlets use strong locking systems. They prevent power cords from coming loose.

- Lockable outlets help data centers stay online. They protect servers and network devices.

- They reduce human errors. They make cable management easier.

- Lockable outlets improve power reliability. They protect against tampering.

- They offer safety features. These include overload protection and surge suppression.

- Lockable outlets help manage power better. They save energy and lower costs.

- These outlets work in many places. They fit data centers, offices, and home systems.

Preventing Accidental Power Disconnections

Accidental power disconnections pose a constant threat to IT infrastructure. Lockable C13 and C19 outlets offer a robust defense against these disruptions. They ensure continuous power delivery to critical equipment.

Secure Locking Mechanisms

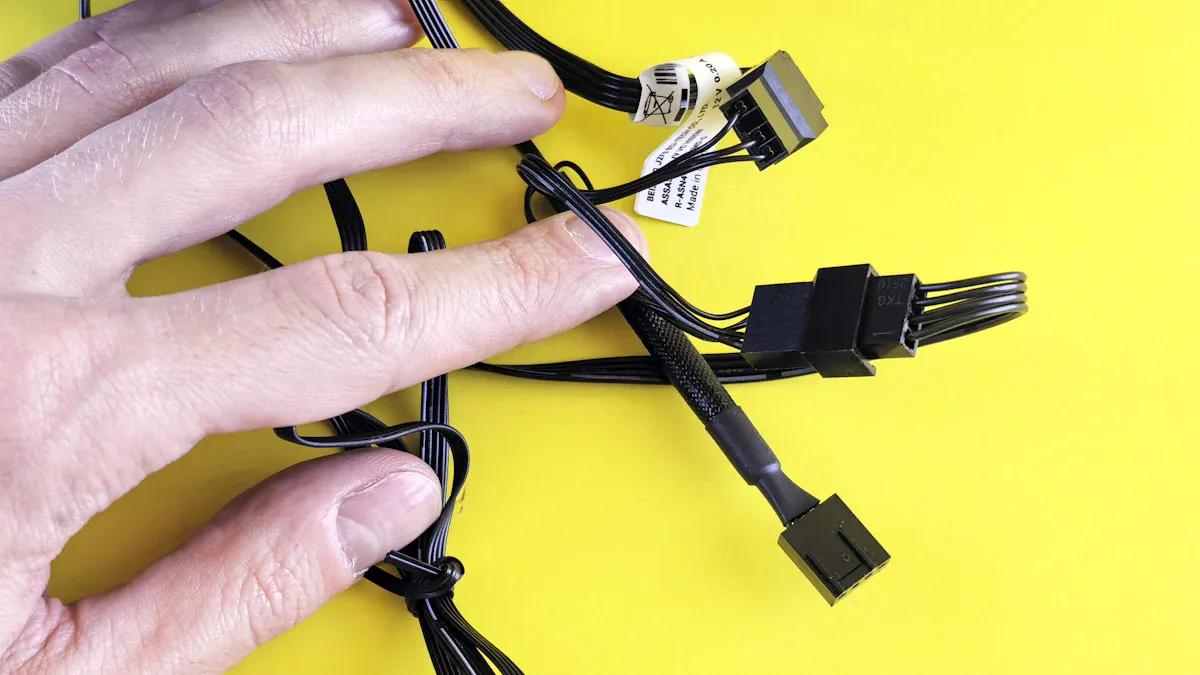

Mechanical Retention Systems

Lockable outlets employ various mechanical retention systems. These systems physically secure power cords to the PDU. For instance, some C13 and C19 connectors feature internal locking mechanisms. These mechanisms pinch the inlet pins, creating a firm grip. Other options include A-Lock and P-Lock systems. A-Lock connectors disconnect by pulling back on red tabs. P-Lock options securely lock the plug into place. V-Lock options are also available for C13, C14, C19, and C20 connectors. Users release these by pressing a lever. V-Lock connectors often feature a bright yellow color for easy recognition. They require a pull-out force of at least 200 N. They engage only with matching inlets. Cost-effective solutions like secure sleeves also exist. These sleeves fit snugly around inlets, connectors, and plugs. They provide a tighter mate, reducing unintentional unplugging without replacing power cords. These diverse mechanical solutions prevent cords from slipping out.

Vibration-Resistant Connections

Mechanical locking mechanisms inherently create vibration-resistant connections. Data centers and other IT environments often experience vibrations. These vibrations can loosen standard power cords over time. The secure grip of lockable outlets prevents this loosening. This ensures power cables remain firmly attached. Equipment operates without interruption, even in dynamic conditions. This robust connection design is crucial for maintaining stability.

Maintaining Critical Equipment Uptime

Data Center Operational Stability

Lockable C13 and C19 outlets significantly enhance connection reliability. This is particularly true in rack power distribution units. They feature mechanical locks. These locks prevent accidental disconnection of power cables. This locking mechanism ensures equipment remains powered. This is vital in environments prone to vibration or movement. It is critical for maintaining uptime in data centers. The design specifically safeguards devices. These devices include computers, PDUs, servers, and network equipment. They are protected from unexpected power loss. A 19”Lockable IEC C13 C19 rack power distribution unit provides this enhanced reliability. It ensures continuous power for critical operations.

Server and Network Device Continuity

Locking connectors directly contribute to server and network device continuity. They reduce the risk of accidental disconnections. This ensures a continuous power supply for critical operations. Plug lock inserts prevent power cords from accidentally disconnecting from C13 output receptacles. This protection is crucial in settings like data centers. Geist U-Locks provide total security against accidental dislodging of cables. This maintains uptime in critical applications. Servers and network devices operate without interruption. This continuity is essential for business operations.

Reducing Human Error

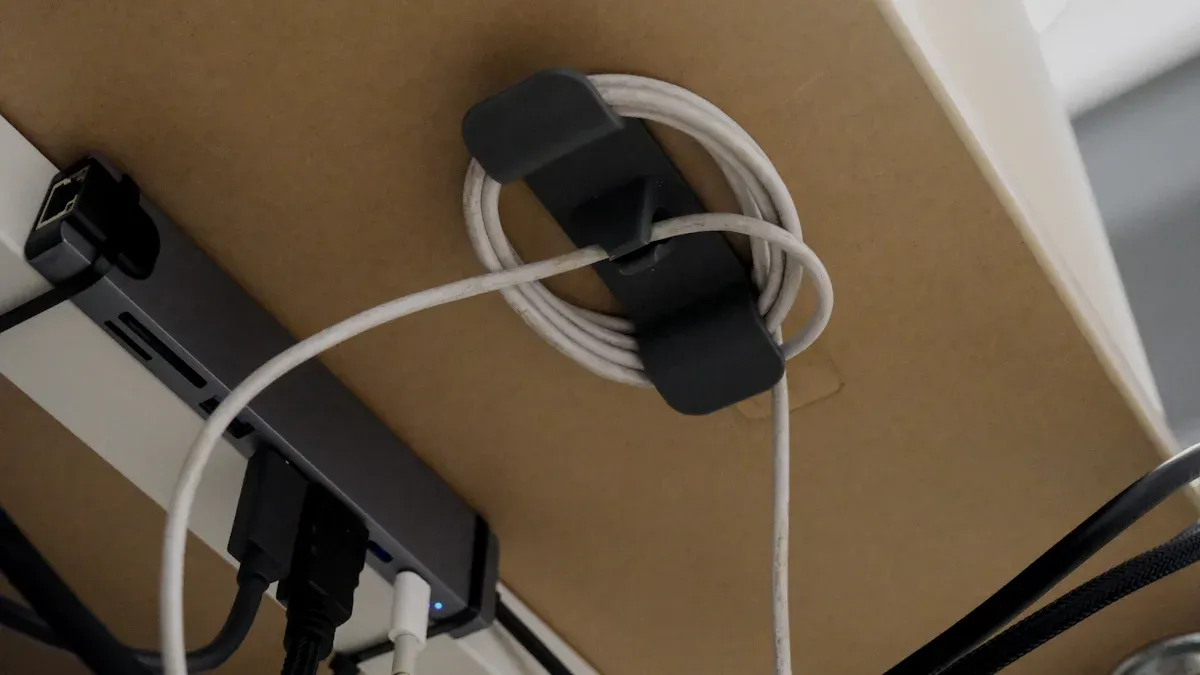

Simplified Cable Management

Human error is a significant cause of accidental power disconnections. Technicians often work in the rear of cabinets. They commission servers, replace power supplies, or route cables. During these tasks, they frequently dislodge power cords accidentally. The design of power cords, especially IEC C13/C14 and high-current IEC C19/C20 connections, contributes to this problem. The weight of connectors and thick cables makes them prone to accidental disconnections. Lockable outlets mitigate this risk. They simplify cable management by securing connections. This reduces the need for constant re-securing. It minimizes human interaction with live connections. This proactive approach prevents errors.

Clear Connection Status Indicators

Lockable outlets provide clear connection status indicators. A securely locked connection visually confirms power integrity. Some locking mechanisms, like the bright yellow V-Lock, offer immediate visual cues. This clarity helps technicians quickly assess connection status. It reduces ambiguity. This minimizes the chance of accidental disconnections during maintenance. Nearly 40% of organizations have suffered a major outage caused by human error. This often stems from staff failing to follow procedures. Clear connection status helps prevent such errors. It ensures proper operational protocols.

Enhanced Reliability and Security for 19”Lockable IEC C13 C19 Rack Power Distribution Unit

Lockable C13 and C19 outlets significantly elevate the reliability and security of power distribution units. They provide a critical layer of protection for sensitive IT equipment. A 19”Lockable IEC C13 C19 rack power distribution unit offers peace of mind through its robust design.

High Retention for Secure Connections

Unbreakable Power Links

Lockable outlets create exceptionally strong power links. These links prevent accidental disconnections. Secure retention sleeves, for example, increase the force required to remove power cables by up to four times. These sleeves are available for both C13 and C19 connectors. They protect equipment from dislodging due to vibration or unintentional disconnects. This enhanced retention ensures power cables remain firmly in place.

Consider the specific retention force standards:

- A C13 connector, when tested for single pin retention (simulating a C14 inlet pin), requires 1.5 Newtons of force for 3 seconds.

- The release of a C14 inlet gauge (all three pins) for a C13 connector requires 50 Newtons of force.

These standards highlight the robust nature of these connections. They ensure a consistently secure power supply.

Consistent Power Delivery

Unbreakable power links directly translate into consistent power delivery. When connections remain secure, the flow of electricity to critical devices never falters. This consistency is paramount for maintaining operational stability in data centers and other demanding environments. A 19”Lockable IEC C13 C19 rack power distribution unit ensures that servers, switches, and other network components receive uninterrupted power. This prevents unexpected reboots or data corruption.

Robust Design and Testing

100% Reliability Assurance

Manufacturers design lockable outlets and PDUs for maximum reliability. They subject these products to rigorous testing. This ensures every component meets stringent quality standards. Many manufacturers adhere to certifications like ISO 9001 (often with AS9100 for manufacturing quality) and UL/IEC 62368-1 and 61010-1 for product design and manufacturing safety. These certifications guarantee a high level of reliability. Other common certifications include UL and CE, which verify general product safety and performance. For specialized applications, such as military use, products may even meet MIL-STDs.

Functionality Verification

Extensive testing verifies the functionality of lockable outlets. This includes checks for electrical safety, mechanical durability, and environmental resilience. Products often carry UL and CE certifications, even with modifications. They also comply with standards like EN 60947-5-1 and EN 60204-1 for integrated safety systems and emergency stop functionalities. This comprehensive verification process ensures the outlets perform as expected under various conditions. It confirms their ability to maintain secure connections and deliver power reliably.

Protection Against Tampering

Physical Security of Connections

Lockable C13 and C19 outlets provide significant physical security for connections. They prevent accidental unplugging, which is a critical aspect of infrastructure security. This mechanical locking feature keeps systems safe and reduces downtime. It ensures connections remain secure even in busy server racks. This contributes to overall system security by maintaining continuous power supply and data flow.

Unauthorized Disconnection Prevention

The physical security offered by lockable outlets also deters unauthorized disconnections. This is crucial in environments where access might be restricted or where malicious intent could pose a threat. Some advanced PDUs, such as switched PDUs, offer the ability to lock outlets for security purposes. These PDUs combine physical security with other management functions like power cycling and sequencing startups. This multi-layered approach enhances the overall security posture of a 19”Lockable IEC C13 C19 rack power distribution unit. It protects against both accidental and intentional power interruptions.

Improved Safety and Protection Features

Lockable C13 and C19 outlets, integrated into a robust rack PDU, offer significant safety and protection features. These features safeguard valuable IT assets and ensure operational continuity.

Overload Prevention and Circuit Protection

Individually Fused Outlets

Some advanced PDUs feature individually fused outlets. Each outlet has its own fuse. This design isolates faults. If one device experiences a short circuit or overload, only its specific outlet loses power. Other connected devices continue to operate without interruption. This granular protection prevents widespread power outages within the rack.

Circuit Breaker Integration

Rack PDUs incorporate circuit breakers for comprehensive overload protection. These components automatically shut down circuits when power loads exceed safe limits. This action prevents overheating and reduces the risk of equipment failure. It protects devices from potential harm caused by power surges or imbalances. Circuit breakers stop the flow of electricity during overloads or short circuits. This prevents damage to devices and reduces fire risks. High-quality PDUs include circuit breakers that adhere to strict safety standards, such as UL 489. These standards enable them to manage large power surges and keep equipment safe.

Surge and Spike Suppression

Safeguarding Sensitive IT Equipment

Power fluctuations, such as surges and spikes, pose a constant threat to sensitive IT equipment. Lockable PDUs often include built-in surge suppression. This feature diverts excess voltage away from connected devices. It protects delicate electronics from damage. This proactive defense extends the lifespan of servers, switches, and other critical hardware.

Minimizing Downtime from Power Fluctuations

Effective surge suppression minimizes downtime caused by power fluctuations. Various technologies achieve this protection:

- Metal Oxide Varistors (MOVs): These components absorb surges by switching to a low-resistance state. They return to high-resistance after the surge passes. MOVs degrade over time with surge absorption.

- Thermally Protected MOVs (TFMOVs): TFMOVs integrate a thermal fuse. This fuse disconnects the MOV if it overheats due to aging or overload. This prevents fire risks.

- Transient Voltage Suppressor (TVS) Diodes: PDUs requiring higher protection use TVS diodes. They act as a final or fine-protection stage. TVS diodes have an ultra-fast response (picosecond-level). They provide precise voltage clamping, handle low-energy/high-speed transients, automatically reset, and do not degrade over time like MOVs.

Effective Heat Dissipation

Preventing Component Overheating

Heat is a primary enemy of electronic components. The Uptime Institute shared that “heat is the number one cause of equipment failure.” Effective heat dissipation within a rack PDU is crucial. Overcrowded or tangled cables block airflow and increase the risk of overheating. Technicians avoid bending, crushing, or twisting cables. These actions can damage the cable structure and interrupt power supply. They separate power and data cables to reduce electrical interference. They use only high-quality, compatible cables. Regular inspection and proper routing prevent tension, kinks, and accidental disconnections. These practices reduce physical stress on cables and connectors, supporting efficient power distribution.

Extending Equipment Lifespan

Proper heat management directly extends equipment lifespan. Technicians follow best practices to ensure effective ventilation:

- Keep vents and fans clear. Avoid placing objects nearby.

- Use perforated rack doors and raised floors to enhance airflow.

- Arrange equipment in hot and cold aisle layouts to optimize cooling.

- Inspect and clean cooling fans and filters regularly.

- Monitor temperature near equipment with sensors to detect hotspots early.

- Organize cables with ties or trays to prevent airflow blockages.

These steps help maintain a safe operating environment. They extend the lifespan of critical power infrastructure. Proper placement of the PDU also improves accessibility and airflow. Industry standards recommend positioning PDUs within arm’s reach for easy maintenance. Vertical mounting maximizes outlet count and saves rack space. Horizontal mounting works best when vertical placement blocks airflow or when the rack’s power load is low. Technicians avoid blocking other equipment. They ensure the PDU does not obstruct airflow, which helps maintain effective heat dissipation. Intelligent PDU technology can provide information such as inlet temperatures at different locations within a rack over time. This aids in planning air movement and cooling. It can also provide alerts based on customizable thresholds. Hot spots can be immediately addressed to improve server uptime.

Optimized Power Management and Efficiency

Lockable C13 and C19 outlets, especially when integrated into intelligent rack PDUs, significantly enhance power management and efficiency. They provide critical tools for optimizing energy use and reducing operational costs.

Advanced Monitoring Capabilities

Real-time Power Consumption Data

Intelligent PDUs offer extensive real-time power consumption data. Administrators can remotely monitor power usage, tracking energy consumption, voltage, and current for each outlet. Features like PIPS® (Per Inlet Power Sensing) monitor Current Load (A), Voltage (V), Power (W), Apparent Power (VA), Crest Factor, Power Factor, and Energy per inlet. Input current monitoring uses easy-to-read LEDs to display current per phase. This helps prevent overloads and simplifies 3-phase load balancing in high-density cabinets. Advanced power monitoring provides real-time insight into power consumption and energy efficiency. This helps improve performance and avoid power quality issues.

Remote Management and Control

Intelligent PDUs provide robust remote management and control capabilities. Unlike basic PDUs, they often allow administrators to remotely turn individual outlets on or off. This feature enhances control and facilitates power cycling for troubleshooting or energy-saving purposes. Remote management enables control from a distance, reducing on-site visits. Network monitoring provides access to valuable data through connections including HTTP(S), SSH, Telnet, SNMP, (S)FTP, SMTP, Syslog, and LDAP(S). Environmental monitoring supports daisy-chained DX2-series SmartSensors, each able to send SNMP-based alerts and email notifications for temperature and humidity.

Efficient Power Distribution and Load Balancing

Accommodating Larger Current Levels

Lockable outlets ensure continuous power supply. They prevent power cords from becoming unplugged due to vibrations or human error. This maintains stable power delivery, which is crucial for accommodating larger current levels in high-density environments. A 19”Lockable IEC C13 C19 rack power distribution unit secures the connection between IT equipment and the PDU. This prevents accidental disconnections that could lead to load drops.

Optimizing Power Consumption

Rack PDU designs facilitate efficient power distribution and load balancing. Outlet wiring often alternates between phases. This design facilitates straightforward cord dressing and more efficient load balancing. Locking outlets secure connections, ensuring continuous power delivery. This is crucial for efficient power distribution. Additionally, alternating outlets on rack PDUs simplify circuit/phase balancing and cable management. Color-coded alternating outlets significantly streamline the deployment process.

Cost Savings and Operational Benefits

Reduced Energy Waste

Efficient Power Distribution Units (PDUs) are 2-3% more efficient than conventional units. They significantly reduce energy losses. Maintaining 400V power to IT equipment racks minimizes transmission losses. This leads to energy cost reductions of approximately 2-3% compared to 208V distribution. This saving increases to approximately 4-5% when compared to 120V distribution. An efficiency gain of 3% is achieved by operating processors at 230V versus 120V.

Lower Operational Expenses

Avoiding voltage conversion from 480V to 208V/120V results in a 4% reduction in transmission loss. The total net improvement from these combined factors is 7%. These efficiency gains directly translate into lower operational expenses for data centers and IT environments. Optimized power management reduces energy consumption and minimizes the need for costly troubleshooting or equipment replacement.

Versatile Applications and Compatibility of Lockable IEC C13 and C19 Outlets

Lockable IEC C13 and C19 outlets offer crucial power security across diverse environments. Their design ensures stable power delivery, making them indispensable for various applications.

Data Center and High-Density Environments

Mission-Critical Infrastructure Support

Lockable C13 and C19 outlets are essential for mission-critical infrastructure. They significantly reduce the risk of accidental disconnections. This ensures a continuous power supply in critical environments. For instance, plug lock inserts prevent power cords from accidentally disconnecting from C13 output receptacles. This locking mechanism protects against accidental disconnection, which is crucial in settings like data centers. Geist U-Locks provide total security against accidental dislodging of cables. This maintains uptime in critical applications. These features safeguard servers, storage arrays, and networking equipment.

High-Density Rack Integration

High-density racks demand reliable power connections. Lockable outlets secure power cables within crowded server cabinets. This prevents disconnections caused by vibrations or accidental bumps during maintenance. Their robust design supports efficient cable management. This contributes to better airflow and reduced thermal stress on equipment. They ensure every device in a densely packed rack receives uninterrupted power.

Enterprise and Office Settings

Secure Workstation Power

In enterprise and office environments, lockable outlets enhance workstation reliability. They prevent accidental power loss to critical desktop computers, monitors, and peripherals. This reduces data loss and productivity interruptions. Employees can work without worrying about sudden power cuts from loose cables.

Network Closet Reliability

Network closets house essential switches, routers, and communication equipment. Lockable C13 and C19 outlets provide stable power to these devices. They prevent accidental disconnections during routine checks or equipment upgrades. This ensures continuous network connectivity for the entire organization.

Home Theater and Prosumer Use

Protecting Entertainment Systems

Home theater enthusiasts and prosumers also benefit from lockable outlets. They secure power to high-end audio-visual components. This includes amplifiers, projectors, and media servers. Accidental disconnections can disrupt movie nights or gaming sessions. Lockable outlets prevent these frustrating interruptions.

Ensuring Audio-Visual Performance

Stable power delivery is vital for optimal audio-visual performance. Lockable outlets ensure a consistent power supply to sensitive equipment. This prevents power fluctuations from affecting sound quality or video output. They help maintain the integrity of the entertainment experience.

Broad Device Compatibility

Lockable IEC C13 and C19 outlets offer extensive compatibility. They integrate seamlessly into existing IT infrastructures. This broad compatibility makes them a versatile choice for various equipment types.

Universal Fit with Standard Cables

Lockable outlets often maintain compatibility with standard power cables. This design allows users to secure connections without replacing their entire cable inventory. Many locking mechanisms reside within the outlet itself or on specialized cables designed to mate with standard inlets. For example, certain lockable C13 outlets accept any standard C14 plug. The outlet then provides the locking retention. This feature simplifies deployment. Organizations can upgrade their PDUs to include locking outlets. They do not need to purchase all new power cords. This approach offers a cost-effective solution for enhancing power security. It ensures a smooth transition for existing setups. Technicians can easily retrofit these solutions. This maintains operational continuity.

Four-in-One Outlet Support (C13, C15, C19, C21)

Some advanced lockable outlets offer remarkable versatility. They support multiple IEC connector types within a single receptacle. These “four-in-one” outlets can accommodate C13, C15, C19, and C21 plugs. This innovative design provides significant flexibility.

- C13 and C15: These are common for servers, switches, and other IT equipment. C15 connectors handle higher temperatures than C13.

- C19: This connector supports higher current devices, such as high-density servers and network switches.

- C21: This is a less common, higher-rated connector, often found in specialized industrial or high-power applications.

This multi-standard support simplifies inventory management. IT departments do not need to stock different PDUs for various equipment power requirements. It also future-proofs infrastructure. Organizations can deploy new hardware with different power needs without modifying their power distribution setup. This flexibility ensures efficient power delivery across a wide range of devices. It reduces complexity in diverse IT environments.

Types and Features of Lockable C13 and C19 Outlets

Lockable C13 and C19 outlets come with various features designed to enhance power security and operational efficiency. Understanding these types helps in selecting the most suitable solution for specific IT environments.

Mechanical Locking Mechanisms

Clip-Based Systems

Clip-based locking systems offer a straightforward and effective method for securing power cords. These systems typically involve small clips or tabs on the connector or the outlet itself. They engage with a corresponding slot or ridge, creating a firm hold. Users can easily connect and disconnect these systems, often with a simple squeeze or pull action. This design balances security with user-friendliness, making them popular in dynamic data center environments.

Screw-In Connectors

Screw-in connectors provide a more robust and semi-permanent locking solution. These systems feature a threaded collar or screw mechanism that tightens the power cord to the outlet. Once tightened, the connection becomes highly resistant to accidental dislodging, vibrations, or tampering. While they require a tool or more effort to secure and release, screw-in connectors offer superior physical security for critical equipment where disconnection is rare.

Color-Coded Options

Easy Identification and Organization

Many lockable C13 and C19 outlets are available in various colors. This color coding serves a practical purpose, allowing for easy identification and organization within crowded racks. Technicians can assign specific colors to different power phases, circuits, or types of equipment. This visual distinction simplifies cable management and reduces confusion during installation or maintenance.

Preventing Misconnections

Color-coded outlets actively help prevent misconnections. By clearly delineating power paths, they reduce the likelihood of plugging a device into the wrong circuit or phase. This minimizes human error, which often leads to downtime or equipment damage. Clear visual cues enhance safety and operational stability in complex IT infrastructures.

Compatibility with Standard Cables

Retrofit Solutions for Existing Setups

Lockable C13 and C19 outlets are designed to be compatible with existing standard power cables. This allows organizations to upgrade their power distribution units without replacing their entire cable inventory. For instance, the IEC 60320 C14 P-Lock securely connects with a standard C13 inlet. Similarly, the IEC 60320 C14 P-Lite is backward compatible with any standard IEC 60320 C13 Outlet, though it will not mechanically lock without a specific locking outlet. This backward compatibility makes retrofitting existing setups a cost-effective solution.

Seamless Integration

The design of these lockable outlets ensures seamless integration into current IT infrastructures. For C19 outlets, the IEC 60320 C20 P-Lock is designed to latch into a C19 Inlet, ensuring a secure connection. This means IT professionals can easily incorporate lockable PDUs into their racks. They do not need extensive re-cabling or system overhauls. This ease of integration minimizes disruption and allows for a smooth transition to enhanced power security.

Lockable IEC C13 and C19 outlets prove indispensable for maintaining uninterrupted power in critical IT environments. They significantly enhance system reliability, bolster security measures, and improve overall safety. These outlets also optimize power management strategies.

- Their broad utility extends across data centers, corporate offices, and even home entertainment systems, highlighting their considerable value.

- Investing in these specialized outlets represents a strategic decision. It ensures robust operational stability and provides crucial protection for valuable equipment.

FAQ

What are lockable C13 and C19 outlets?

Lockable C13 and C19 outlets are specialized power receptacles. They feature mechanisms to secure power cords. This prevents accidental disconnections. They ensure continuous power delivery to critical equipment. These outlets are common in rack power distribution units (PDUs).

Why are lockable outlets crucial for data centers?

Lockable outlets are crucial for data centers. They prevent unexpected power loss to servers and network devices. This maintains operational stability. They also reduce downtime caused by human error or vibrations. This protects mission-critical infrastructure.

How do lockable outlets prevent accidental power disconnections?

Lockable outlets use mechanical retention systems. These systems physically secure the power cord to the outlet. They create a firm, vibration-resistant connection. This prevents cords from slipping out. It ensures a continuous power supply.

Are lockable outlets compatible with existing power cables?

Many lockable outlets offer compatibility with standard power cables. This allows users to secure connections without replacing all cables. Some outlets have internal locking mechanisms. These mechanisms work with standard plugs. This simplifies integration into current setups.

What safety features do lockable outlets offer?

Lockable outlets enhance safety. They prevent accidental disconnections. This reduces the risk of electrical hazards. When integrated into PDUs, they often include overload protection and surge suppression. These features safeguard sensitive IT equipment.

How do lockable outlets contribute to power management efficiency?

Lockable outlets ensure consistent power delivery. This is vital for efficient power distribution. When combined with intelligent PDUs, they enable real-time monitoring. They also allow remote control. This optimizes power consumption and reduces energy waste.

Can lockable outlets be used in office or home settings?

Yes, lockable outlets are versatile. They enhance reliability in office workstations and network closets. In home settings, they protect entertainment systems. They ensure stable power for high-end audio-visual equipment. This prevents frustrating interruptions.

Post time: Nov-10-2025