The manufacturing process of PDUs (Power Distribution Units) typically involves several stages, including design, component assembly, testing, and quality control. Here's a general overview of the PDU manufacturing process:

* Design and Specifications: The initial stage involves designing the PDU and defining its specifications based on the intended use and market requirements. This includes determining factors such as power capacity, input and output connectors, form factor, monitoring features, and any specialized functionalities.

* Component producing / Sourcing: Once the design is finalized, manufacturers produce or source the necessary components for the PDU production. These components can include circuit breakers, power outlets, input plugs, control boards, cables, wiring, housing materials, and other associated hardware.

* Component Assembly: The sourced components are assembled according to the PDU's design specifications. Skilled workers or automated assembly lines connect the various components, wires, and circuits, following specific guidelines and using specialized tools. This step also involves the installation of monitoring modules, communication interfaces, and any additional features incorporated into the PDU design.

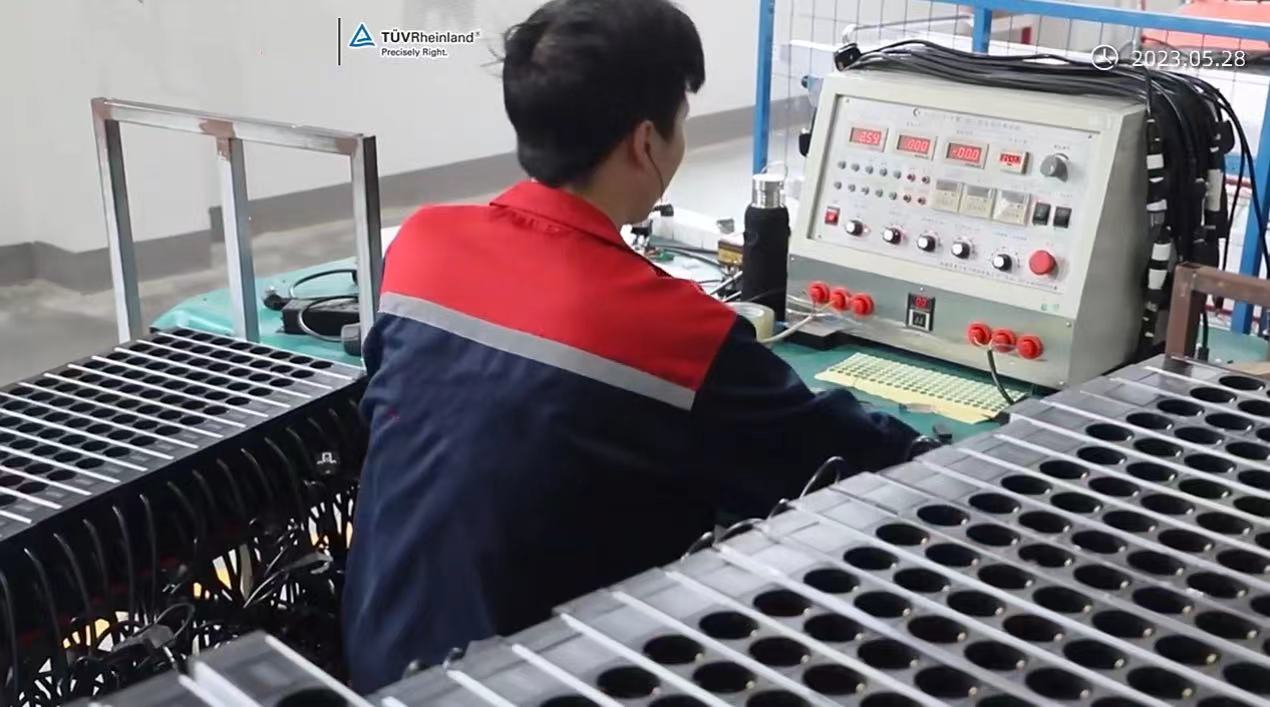

* Testing and Quality Control: After the assembly, the PDUs undergo rigorous testing to ensure their functionality, safety, and compliance with relevant industry standards. Various tests are performed, including electrical testing, load testing, temperature testing, and verification of monitoring and control features. Quality control measures are implemented to identify and rectify any manufacturing defects or inconsistencies.

* Firmware/Software Installation: If the PDU incorporates firmware or software for monitoring and control purposes, the necessary programming is installed during this stage. This can involve flashing the firmware onto microcontrollers or programming the PDU's software interface.

* Packaging and Labeling: Once the PDUs pass the testing and quality control phase, they are packaged appropriately for shipment and storage. The packaging includes protective materials to prevent damage during transit. Product labels, including model numbers, specifications, safety information, and regulatory compliance markings, are applied to the packaging.

It's important to note that specific manufacturing processes may vary between different manufacturers, and they may have additional steps or variations based on their specific production methods, technologies, and quality control procedures.

Newsunn pays much attention to the final test, and requires 100% inspection and pass rate before shipping. In the past years, we never received any quality or safety complaint from our customers. So Newsunn power distribution unit is always reliable.

Post time: Jun-28-2023