Understanding country-specific PDU standards is crucial for 2025 data center operations. Organizations must evaluate essential factors like current power requirements and future scalability. Choosing the right European rack power distribution unit for UK, German, or French facilities requires careful consideration. Whether implementing a Basic PDU or an advanced Intelligent PDU, informed decisions optimize IT infrastructure performance and reliability.

Key Takeaways

- Choose the right power distribution unit (PDU) for your data center. This helps your IT equipment work well.

- Different countries in Europe use different power sockets. The UK, Germany, and France each have their own types.

- Certifications like CE and UKCA show that a PDU is safe and meets local rules. Always check for these marks.

- Intelligent PDUs are smart power strips. They let you watch power use and control devices from far away. Basic PDUs just give power.

- Mounting PDUs vertically in a rack saves space for your computers. It also helps keep them cool.

- Distribute power evenly across all connections. This stops power problems and keeps your equipment safe.

- Plan for future growth when buying PDUs. Modular designs and higher power capacity help your system grow with your needs.

European Rack PDU Fundamentals for 2025

What is a Rack PDU?

Defining Rack PDU Functions

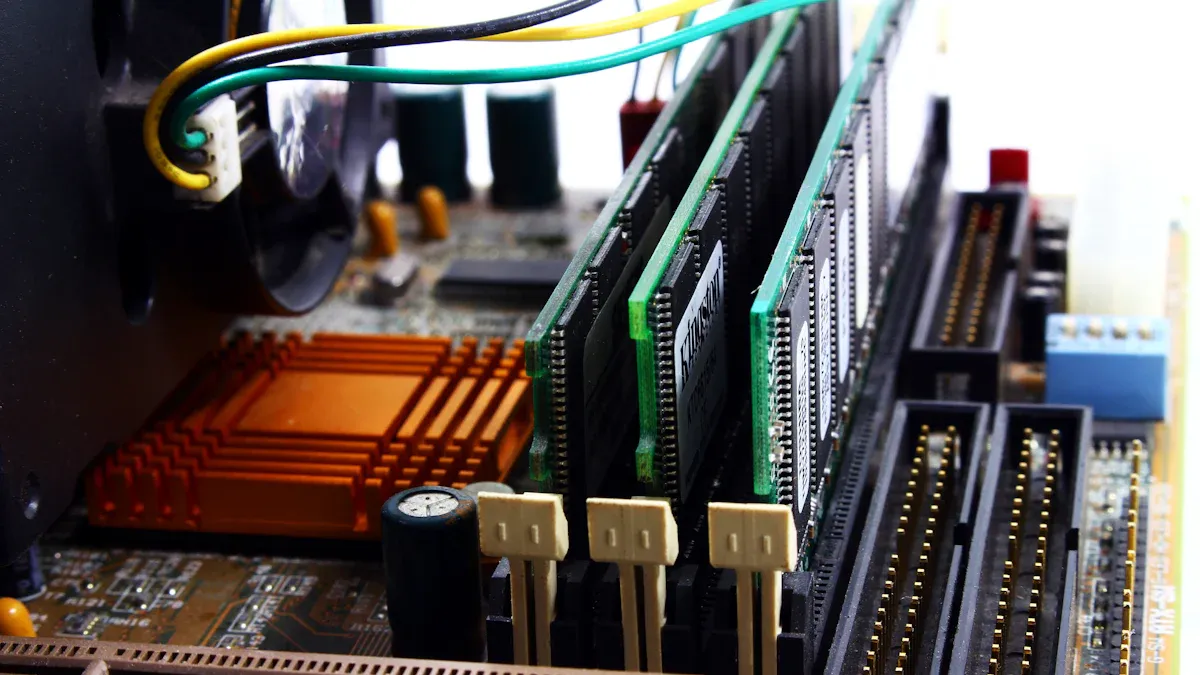

A rack PDU distributes power from the building to various equipment within a data center or rack. These devices install in racks to provide additional outlets and enhance the power supply to the equipment. Rack PDUs are crucial for enabling efficient power distribution, management, and monitoring in modern data centers. They provide metering and monitoring capabilities for real-time insights into power usage. This helps identify inefficiencies, optimize distribution, and achieve higher energy efficiency.

Importance for European Data Centers

Rack PDUs enhance the resilience of data center infrastructure. They offer redundant power features and remote management capabilities. This ensures continuous operation of critical equipment. Advanced rack PDUs can also include capabilities for environmental monitoring. This is vital for maintaining optimal conditions in European data centers.

Key PDU Types for 2025

Basic PDU Features

A basic PDU acts as an industrial-grade power strip. It distributes AC or DC power from one source to multiple devices. Most models are rack-mounted. This type does not generate power or offer advanced control features. It focuses on reliable and efficient power delivery without monitoring or switching capabilities. Organizations primarily deploy basic PDUs in small-scale or budget-conscious environments. They suit SMB data centers and enterprise racks well. They offer cost-effective management in racks with lower power capacities. Basic PDUs are best for environments where simplicity and reliability are the main priorities.

Metered PDU Benefits

Metered PDUs offer improved data center management. They track, control, and regulate power usage locally and remotely. This leads to increased efficiency, dependability, and reduced operational expenses. They provide great power monitoring and control. Administrators can track power at equipment or PDU levels. They can also set user-defined parameters and receive notifications before issues occur. Metered PDUs enhance energy efficiency through load balancing and reduced waste. They also improve cost management by identifying energy-intensive equipment.

Monitored PDU Capabilities

Monitored PDUs provide a comprehensive view of power usage. This view is available both at the rack and via remote access. They ensure reliable power distribution to critical IT equipment. These PDUs offer advanced power monitoring down to the load group. This allows for cross-platform rack-level power and thermal trending analysis. They also support environmental monitoring within the cabinet using various sensors. This ensures optimal operating conditions. A European rack power distribution unit for UK facilities often utilizes these features for enhanced oversight.

Switched PDU Control

Switched rack PDUs offer controlled on/off switching for individual outlets. This enables remote power recycling. They allow for delayed power sequencing of equipment. These PDUs provide management over individual outlet usage. Remote outlet-level controls facilitate power cycling to reboot locked-up equipment. They also help avoid unauthorized use of individual outlets. Users can define the order for powering up or down attached equipment.

Intelligent PDU Advantages

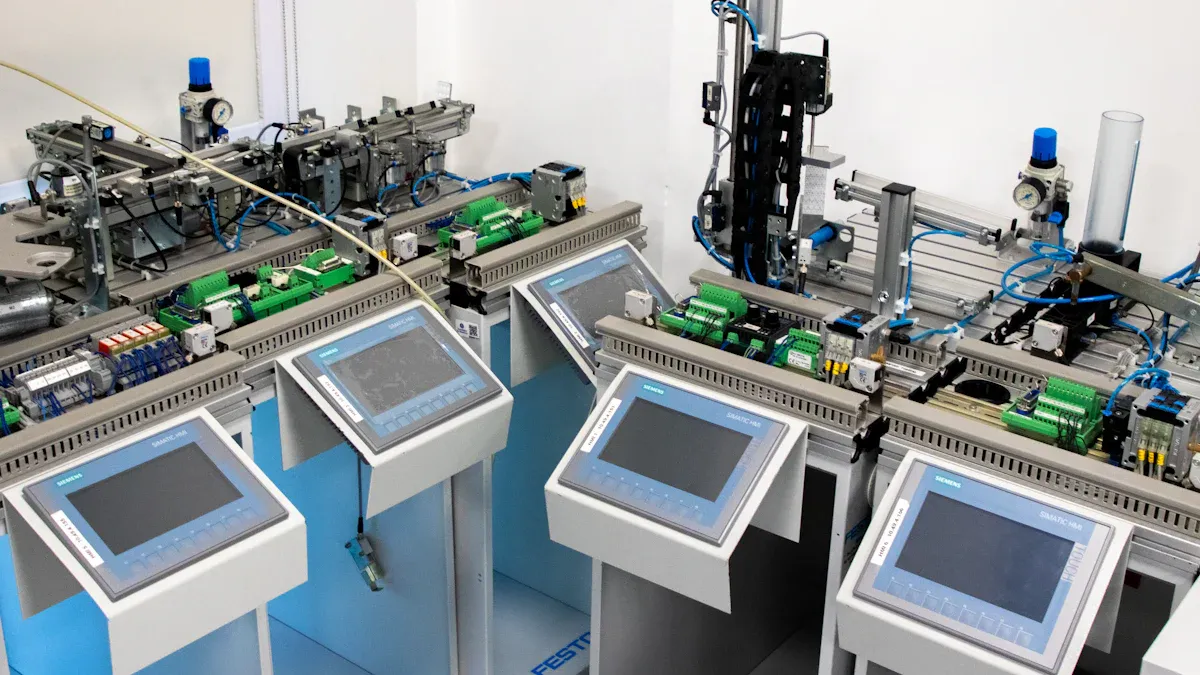

Intelligent PDUs provide real-time power monitoring and rack sensor information. This includes temperature and humidity. This data is accessible via web browser or CLI. They improve uptime and staff productivity. IT administrators can monitor power at the PDU level, set user-defined thresholds, and receive alerts. Remote rebooting of servers and IT equipment via outlet-level switching also contributes to improved uptime and productivity.

Core PDU Specifications

Voltage Standards Across Europe

The standard voltage requirement for rack PDUs in the UK, Germany, and France is 250VAC. Europe commonly provides 230V power for servers and networking equipment.

Amperage Ratings Explained

The current rating for rack PDUs in these regions is typically 16A. In data centers, 400V three-phase Wye rack PDUs are a common practice. They deliver high power to densely packed racks.

Single-Phase vs. Three-Phase Power

These 400V three-phase PDUs provide three circuits. Each circuit supplies 230V (derived from 400V / 1.732). This voltage is suitable for much data center equipment. Single-phase power is simpler and common for lower power needs. Three-phase power offers greater efficiency and capacity for high-density environments.

Country-Specific PDU Requirements: UK, Germany, and France

Deploying IT infrastructure across Europe demands a precise understanding of each country’s specific PDU standards. Ignoring these local requirements leads to compliance issues, operational inefficiencies, and potential safety hazards. This section details the essential PDU considerations for the United Kingdom, Germany, and France.

United Kingdom (UK) PDU Considerations

Organizations operating in the UK must adhere to distinct electrical standards for their rack PDUs.

UK Socket Types: BS 1363 (Type G)

The UK primarily uses specific socket types for power distribution. The most common single-phase AC power plug and socket in the UK is BS 1363. This standard, also known as ‘Type G’ in the IEC 60083 standard, features shutters on the neutral and line socket holes and includes a fuse in the plug. Rack Power Distribution Units (PDUs) designed for the UK market explicitly feature BS 1363 UK Sockets. An older standard, BS 546, also exists for three-pin AC power plugs and sockets. While still permitted in older installations or special applications if the socket has shutters, BS 1363 remains the dominant type for modern data centers.

UK Voltage and Amperage Standards

UK data centers typically operate on a standard voltage of 250VAC. The common current rating for rack PDUs in the UK is 16A. These specifications align with broader European standards but require specific socket compatibility.

UK Certification: UKCA and CE

Compliance with electrical certifications is mandatory for rack PDUs sold and operated in the UK. The UKCA Mark became effective on January 31, 2020, and applies to products sold in Great Britain. It is expected to become mandatory after the Brexit transition period. Northern Ireland, however, continues to recognize the CE mark. Rack PDUs generally need to comply with the EU Low-Voltage Directive (LVD), which covers electronic equipment operating between 50V and 1000V AC or 75V and 1500V DC. Furthermore, PDUs should conform to IEC 60950-1 and IEC 62368-1 Standards under the IEC CB Scheme. IEC 62368-1, compulsory since December 20, 2020, replaces older standards, unifying safety requirements for IT, communications, and audio-visual equipment. Selecting a compliant European rack power distribution unit for UK facilities ensures operational safety and market access.

Germany PDU Considerations

German data centers have specific requirements for PDU configurations and certifications.

German Socket Types: Schuko (CEE 7/3 and CEE 7/4)

Germany primarily uses Schuko sockets, specifically CEE 7/3 (socket) and CEE 7/4 (plug). These sockets feature side-mounted earthing clips rather than a dedicated earth pin. The PDU socket type specifically referred to for Germany is consistently labeled as ‘Germany Type’. These sockets are available in various configurations, including 6, 8, and 9 ways, and can be found in 19-inch rack-mountable versions. They are designed for industrial applications with standard grounding, rated for 250V and 16A.

German Voltage and Amperage Standards

Similar to the UK, German electrical systems typically use a standard voltage of 250VAC. The common amperage rating for rack PDUs in Germany is 16A, supporting the power demands of modern IT equipment.

German Certification: VDE and CE

Rack PDUs in Germany require specific certifications to ensure safety and quality. The CE mark is essential for market access within the European Union. Additionally, a ‘Germany Type 19″ PDU Rack Data Center Power Distribution Unit’ is explicitly stated to have CE/ROHS/YUV/SGS Certification. Factories producing these PDUs often obtain CE, ROHS, and SGS authentication for their products, demonstrating adherence to environmental and quality standards. VDE certification is also highly regarded in Germany, signifying compliance with German electrical safety standards.

France PDU Considerations

French data centers also have unique PDU requirements, particularly regarding socket types and certifications.

French Socket Types: Type E (CEE 7/5)

France utilizes Type E sockets, also known as CEE 7/5 (socket) and CEE 7/6 (plug). These sockets feature a round earth pin protruding from the socket, which mates with a hole in the plug. Power Distribution Units (PDUs) designed for industrial applications in France utilize ‘France Type 6 Sockets‘. PDUs available for use in France are described as having ‘French sockets‘, and rack PDUs intended for France feature outlets in ‘French style‘.

French Voltage and Amperage Standards

French electrical systems operate at a standard voltage of 250VAC. The typical amperage rating for rack PDUs in France is 16A, consistent with other major European countries.

French Certification: NF and CE

For rack PDUs sold and operated in France, the CE certification is required for market access in Europe. Other important certifications for safety and quality include RoHS, UL 60950-1, UL 489, and ISO9001. The NF mark (Norme Française) is a national certification mark in France, indicating compliance with French and European standards, and often complements the CE mark for products sold in the country.

Interoperability for Multi-Country Deployments

Organizations often operate data centers in multiple European countries. This requires careful planning for PDU interoperability. Different national standards for sockets and certifications create challenges. However, strategic choices can ensure seamless power distribution across diverse locations.

Addressing Mixed Socket Needs

Deploying IT equipment across the UK, Germany, and France means dealing with distinct socket types. The UK uses BS 1363 (Type G), Germany relies on Schuko (CEE 7/3 and CEE 7/4), and France employs Type E (CEE 7/5). Data center managers must address these mixed socket needs. One solution involves using PDUs specifically designed with a mix of these outlets. Some manufacturers offer universal PDUs that accept multiple plug types, though these are less common for high-density rack environments. More often, facilities deploy country-specific PDUs within each region. They then manage the overall power infrastructure through a unified system. This approach ensures equipment compatibility and adherence to local safety standards.

Standardizing Across Regions

Achieving standardization across regions is crucial for efficient multi-country operations. Ensuring seamless integration with legacy infrastructure remains a critical factor for PDU adoption. Manufacturers must focus on robust, scalable, and cost-effective solutions to fully capitalize on market demand. Adherence to international standards remains a critical factor for PDU adoption.

Germany’s data centers, for example, prioritize interoperability through adherence to industry standards. These include IEC, IEEE, and ISO. These standards ensure seamless communication between hardware and software components. PDUs adhere to industry standards such as SNMP (Simple Network Management Protocol), Modbus, and REST APIs. This facilitates interoperability with various management platforms. These standards enable centralized control and monitoring across diverse hardware vendors. APIs allow for automation scripts, custom dashboards, and integration with broader facility management systems.

Compliance with regulations such as GDPR and local energy directives is essential. Furthermore, compliance with safety and electrical standards (like UL, IEC) ensures PDUs meet rigorous safety and performance criteria. Many operators adopt open standards to facilitate future upgrades. They also incorporate emerging technologies like smart grids and IoT devices. This supports flexible, scalable, and resilient power architectures. Compatibility with emerging standards like MQTT and BACnet further enhances interoperability as data centers adopt more IoT devices. However, the lack of complete standardization across different manufacturers’ bypass functionalities can pose interoperability challenges. Organizations must carefully evaluate PDU features to mitigate these potential issues.

Advanced PDU Features for 2025 European Operations

Modern data centers in Europe demand more than basic power distribution. Advanced rack PDUs offer sophisticated features. These capabilities enhance efficiency, reliability, and security. They are crucial for managing complex IT environments.

Environmental Monitoring Integration

Effective data center management relies on understanding the physical environment. Advanced PDUs integrate sensors to provide critical insights.

Temperature and Humidity Sensors

Advanced rack PDUs connect with various environmental sensors. These sensors monitor conditions within the rack. For example, the APC NetShelter Rack PDU 10000 Temperature & Humidity Sensor protects IT equipment. It guards against overheating or moisture issues. These sensors plug directly into environmental sensor ports on advanced PDU models. This allows for integrated monitoring and notifications. Intelligent solutions like Legrand’s SmartSensors offer plug-and-play integration. They work with intelligent rack PDUs and inline meters. This eliminates the need for separate controllers. These sensors provide accurate environmental data. They send this data instantly to DCIM software. This allows for real-time monitoring and trend analysis. Other integrated sensors can detect water leaks, maintain optimal air pressure, and ensure cabinet security.

Airflow Management

Monitoring airflow is vital for cooling efficiency. Integrated sensors help manage airflow. They identify hot spots and ensure proper air circulation. This prevents equipment damage and reduces energy consumption. Effective airflow management contributes to a stable operating environment.

Remote Management and Control

Remote capabilities are essential for managing distributed IT infrastructure. Advanced PDUs offer robust remote management.

Network Connectivity and Protocols

Advanced PDUs feature strong network connectivity. Ethernet-based protocols enable remote control of power cycles. They also monitor energy consumption with Smart PDUs. NBYOSUN’s German Switched IP 483mm 8 Ways Rack PDU supports TCP/IP and RS-485 hybrid networking. Simple Network Management Protocol (SNMP) is a common remote management capability. These protocols allow administrators to manage PDUs from any location.

User Interfaces and Software

PDUs provide intuitive user interfaces. These include web browsers and command-line interfaces (CLI). Dedicated software platforms or DCIM systems integrate PDU data. This offers a centralized view of power usage and environmental conditions. Administrators can configure settings, receive alerts, and perform remote actions.

Security Features for PDU Access

Protecting PDU access and data is paramount. Advanced PDUs include robust security features.

Authentication and Authorization

Strong password policies are essential for security. These policies include minimum character requirements. They also forbid reusing recent passwords. Forced password changes for default credentials and periodic password expiration are common. Firewalls prevent unauthorized network access. IP-Based Access Control Lists (IP ACL) filter traffic. Role-Based Access Control (RBAC) manages access based on user roles. Defense in Depth strategies block access after repeated failed login attempts. They also time out inactive sessions.

Data Encryption and Logging

Encryption is critical for all data transmitted to or from PDUs. This includes HTTPS (TLS 1.2/1.3 with AES 128/256-bit ciphers). SSH uses public key authentication. SNMP v3 offers various encryption algorithms. StartTLS secures credential transport to remote authentication servers. Certificates (X.509 digital certificates) ensure authorized users in secure connections. They protect against man-in-the-middle attacks. Secure Boot processes guarantee that only trusted software executes during system startup.

Optimizing Power Distribution with European Rack Power Distribution Unit for UK, Germany, and France

Optimizing power distribution is critical for efficient and reliable data center operations. Strategic PDU placement, load balancing, and redundancy options ensure maximum uptime and energy efficiency. These practices are especially important for a European rack power distribution unit for UK, German, and French facilities.

Power Density and Rack Space Optimization

Data centers constantly seek ways to maximize space and power delivery. PDU placement and configuration play a significant role in achieving these goals.

Vertical vs. Horizontal PDU Placement

Choosing between vertical and horizontal PDU placement impacts rack space utilization. Horizontal PDUs typically occupy 1U or 2U of valuable rack space. This reduces the available area for IT equipment like servers and switches. In contrast, vertical PDUs, often called “0U PDUs,” mount along the sides or rear of the cabinet. This placement keeps the central rack area open for critical devices. Vertical installation frees up valuable rack space for essential equipment. Their compact size, sometimes as little as 2 inches wide and deep, allows installation in tight spaces. This maximizes usable rack space for IT equipment in high-density environments.

Vertical PDUs also support high-density deployments by offering more outlets and higher power capacities. Many provide up to 54 outlets, significantly more than the 8 to 16 outlets on most horizontal PDUs. They can deliver power capacities from 10kW to over 57.6kW. Input currents range from 16A to over 100A. Some models even support up to 90kW and 125A. By mounting on the rack’s upright rails, vertical PDUs preserve critical rack unit space for IT equipment. This allows for dense server deployments. Data centers can power up to 60 devices in a single rack. This is ideal for environments with many servers. Organizations can deploy more servers and network devices without expanding their physical footprint.

Furthermore, vertical PDUs improve airflow by not blocking rack unit space. They facilitate better cable management. Their ultra-low-profile design increases airflow efficiency. It does not obstruct the path of cool or hot air. Ample space remains at the back of the cabinet for cables and air movement. This reduces hot spots. Proper cable management, made easier by vertical mounting, prevents airflow blockage. It helps maintain consistent temperatures.

High-Density Outlet Configurations

High-density outlet configurations are essential for modern data centers. These configurations allow more devices to connect to a single PDU. This reduces the number of PDUs required per rack. It also simplifies cable management. Many vertical PDUs offer a large number of outlets. This supports racks filled with numerous servers and network devices. This design optimizes power delivery within a compact footprint.

Load Balancing and Phase Distribution

Effective load balancing is crucial for maintaining the efficiency and stability of a power distribution system. It prevents inefficiencies and potential equipment damage.

Distributing Load Across Phases

Uneven loads across the three phases can lead to inefficiencies, increased energy costs, and potential equipment damage. This includes overheating or circuit breaker trips. Balanced loads ensure each phase carries an equal share of the total power demand. This optimizes PDU performance. It extends equipment lifespan. It also prevents downtime, especially in high-demand environments like data centers.

To achieve load balance across PDU phases, organizations should follow specific steps:

- Inventory Devices: List all connected devices and their power requirements.

- Assign Devices: Distribute devices evenly across the three phases based on their power consumption.

- Monitor Load: Use metered or smart PDUs to monitor real-time load data. Make adjustments as needed. Tools like a 3-phase PDU calculator can help analyze phase-wise load distribution. They identify imbalances.

A key best practice for distributing electrical load across PDU phases is to ensure all three phases are as balanced as possible. This minimizes unanticipated disruptions and wasted electricity. Unbalanced power draw can lead to stranded capacity, increased wasted electricity, and potential cascading failures upstream.

Preventing Overload Scenarios

Balanced power distribution is vital for preventing overload scenarios. When loads are uneven, one phase can become overloaded. This triggers circuit breakers and causes downtime. Advanced PDUs actively monitor phase balancing. They alert teams when imbalances exceed a set threshold. This proactive monitoring helps data center managers redistribute loads before an overload occurs. It ensures continuous operation and protects valuable IT assets.

Redundancy Options for Reliability

Reliability is a cornerstone of data center operations. Redundancy options for PDUs significantly enhance system uptime.

Dual PDU Configurations

Dual PDU configurations provide a redundant power supply. This ensures continuous power delivery even if one power source fails. This setup eliminates single points of failure. It utilizes two independent power feeds. If one fails, the other takes over. This is crucial for maintaining uptime and meeting industry standards like Tier 2 and Tier 3. Dual PDU configurations offer N+1 redundancy. This guarantees at least one backup power source is always available. They also facilitate load balancing. This distributes power between two sources to maintain system stability. This prevents downtime. It keeps equipment powered during source changes. It also prevents data corruption or equipment damage. Combining two PDUs into a single chassis optimizes rack space. It simplifies power distribution management.

Automatic Transfer Switch (ATS) Integration

Automatic Transfer Switch (ATS) integration further enhances reliability. An ATS operates without manual intervention. It seamlessly switches between power sources in less than 10 milliseconds. This maintains power without interruption. It reduces human error. When one power source fails, the ATS automatically transfers the load to the secondary source. This ensures uninterrupted power to critical IT equipment. This feature is essential for environments demanding continuous operation.

Future-Proofing Your European Rack PDU Investment

Investing in rack PDUs requires foresight. Organizations must consider future growth and technological advancements. This ensures their power infrastructure remains robust and adaptable.

Scalability for Growth

Data centers constantly evolve. Their power distribution systems must scale with increasing demands.

Modular PDU Designs

Modular PDU designs offer significant advantages for future scalability. These managed PDUs allow facilities to expand power distribution as needed. This supports cost efficiency, future-proofing, and operational resilience. Modular design optimizes delivery. It matches IT needs, allowing for right-sizing infrastructure as IT needs grow. This provides capacity quickly for projects or temporary adjustments. It ensures optimal resource utilization. It also avoids costly over or under-provisioning.

Power distribution units and remote power panels configure as needed. They are scalable regarding the number of outputs and required output power. This ensures continuous power to critical applications. Market-leading systems reduce certification costs. They also facilitate easy post-installation alterations. This includes changing or extending the number of connected servers. Modular PDUs offer customizable configurations and scalability. Traditional PDUs have fixed designs that limit adaptability. Modular designs represent a significant advancement. They offer scalability, efficiency, reliability, and cost-effectiveness. As technology evolves, flexible and adaptable solutions like modular PDUs become more important. They help businesses prepare for future power challenges. They also create sustainable, efficient infrastructure.

Modular and scalable PDU solutions enable data centers to grow easily. They save costs and support future technology needs. They prepare data centers for future growth and evolving technology demands. They allow seamless expansion without major reinvestment. They also support new workloads like AI and high-performance computing. Modular designs facilitate rapid deployment and incremental capacity expansion. Operators right-size power delivery. They defer large upfront investments. This approach supports customizable configurations. It ensures compatibility with changing environments and workloads. Data centers adapt quickly, maintain operational efficiency, and meet compliance requirements as technology evolves.

Modular designs also offer several key benefits:

- Fault tolerance ensures continued operation even if a module fails.

- Concurrent maintenance allows servicing of individual modules without interrupting the load.

- Logistics-friendly modules simplify transport and installation.

- Scalable designs reduce planning and commissioning complexity.

Higher Power Capacity Planning

Planning for higher power capacity is essential. Data centers must anticipate increased power demands from new technologies. This includes AI and high-performance computing. Selecting PDUs with sufficient headroom prevents costly upgrades later.

Budget vs. Features Analysis

Choosing the right PDU involves balancing initial costs with long-term benefits.

Cost-Benefit of PDU Types

The choice between basic and intelligent PDUs depends on priorities. Basic PDUs suit small-scale operations with basic load monitoring. They are chosen when immediate cost savings are paramount. Intelligent PDUs, despite higher initial costs, offer advanced functionality and long-term savings. They are essential for modern data centers. These centers aim to reduce downtime costs, optimize energy usage, and ensure future-proof IT environments.

| Feature | Basic PDU | Intelligent PDU |

|---|---|---|

| Power distribution | Yes | Yes |

| Multi-point metering | No | Yes |

| Sequenced outlet power cycling | No | Yes |

| Remote management | No | Yes |

| Environmental monitoring | No | Yes |

| Asset tracking and security | No | Yes |

Long-Term Value Considerations

Intelligent PDUs offer significant long-term value. They reduce downtime costs, potentially saving up to $5,600 per minute. They also provide cabinet savings through automated power budgeting, estimated at $15,000–$20,000 per cabinet. Energy waste reduction can reach up to 20%. Maintenance response time improves by 40%. These benefits outweigh the higher initial investment.

Emerging PDU Technologies

The PDU landscape constantly evolves. New technologies enhance efficiency and management.

Smart PDU Innovations

Smart PDU innovations include AI and Machine Learning integration. This enables predictive maintenance and smarter energy management. A sustainability focus emphasizes eco-friendly materials and energy-saving technologies. Enhanced monitoring and management features include real-time monitoring, cloud-based control, and outlet-level metering. High-density rack PDUs meet increased power demands. Some racks reach up to 200 kW. Edge computing requires robust, remotely manageable PDUs. These include real-time outlet monitoring, remote switching, and environmental sensors for harsh environments.

Integration with Data Center Infrastructure Management (DCIM)

Integration with DCIM systems is crucial. It allows for comprehensive oversight. Real-time monitoring tracks power usage at both unit and outlet levels. Outlet-level analytics support load balancing and detect power anomalies. IoT and AI integration enable predictive maintenance and data-driven decisions. Environmental sensor integration optimizes cooling and prevents equipment damage. User-defined alarms and alerts notify teams of abnormal power consumption.

Installation and Best Practices for European Rack PDUs

Proper installation and adherence to best practices are crucial for maximizing the efficiency and reliability of European rack PDUs. These steps ensure optimal performance and safety for critical IT infrastructure.

Proper Cabling and Cable Management

Effective cable management prevents issues and maintains system integrity. It supports both performance and safety.

Organizing Power Cables

Organizing power cables within a rack is essential. Teams use Velcro ties to bundle cables. This allows for easy adjustments when needed. Color-coded cables help differentiate between power supplies and data types. This simplifies identification. Keeping fiber and copper cables separated prevents interference. Clearly labeling all cables ensures quick identification during troubleshooting. Planning cable routes before installation helps maintain organization and airflow. Utilizing cable management racks with slots and hooks prevents tangling.

Preventing Obstruction and Damage

Proper cable management also prevents obstruction and damage. Labeling both ends of each cable identifies connected equipment. This simplifies troubleshooting and maintenance. Cable trays, ducts, and raceways route cables neatly. This prevents tangling and reduces damage risk. Securing cables with ties or Velcro straps avoids over-tightening. Over-tightening can damage cables. Cables must not obstruct airflow or access to other equipment. Separating power cables from data cables reduces electromagnetic interference.

Safety Considerations and Grounding

Safety is paramount in data center operations. Adhering to electrical standards and ensuring proper grounding protects personnel and equipment.

Adhering to Electrical Safety Standards

Rack PDUs must comply with strict electrical safety standards. The CE Mark indicates compliance with EU safety standards for electronic devices. The IEC CB Scheme certifies products for global use. It ensures they meet international safety standards. NEMKO Certification provides additional safety assurance for universal PDUs. The UKCA Mark is required for products marketed in Great Britain. It is similar to the CE mark. Adherence to EN50110-1 2013 requirements is crucial for the safe installation and maintenance of data center PDUs. Key IEC (International Electrotechnical Commission) Standards include:

- IEC 60950-1: Standard for Information Technology Equipment – Safety.

- IEC 62368-1: Standard for Audio/Video, Information and Communication Technology Equipment – Safety.

- IEC 60320: Standard for Appliance Couplers for Household and Similar General Purposes.

Ensuring Proper Grounding

Proper grounding is a fundamental safety measure. It protects equipment from electrical surges and prevents electric shock. All rack PDUs and connected equipment must have a secure and verified ground connection. This dissipates excess electrical energy safely.

Regular Maintenance and Monitoring

Consistent maintenance and monitoring extend the lifespan of PDUs and prevent unexpected outages.

Scheduled PDU Inspections

Regular inspections are vital for PDU health. Facilities should conduct scheduled PDU inspections at least once a year. Some operations benefit from two PM inspections per year. These inspections identify wear, loose connections, or potential failures before they cause downtime.

Continuous Power Monitoring

Continuous power monitoring provides real-time insights into PDU performance. It tracks power consumption, voltage, and current. This allows teams to detect anomalies quickly. Early detection helps prevent overloads and ensures stable power delivery to critical IT equipment.

Selecting a European rack PDU in 2025 demands careful planning. Organizations must prioritize local standards, intelligent features, and scalability. Adhering to country-specific requirements, such as those for a European rack power distribution unit for UK facilities, ensures compliance and safety. Intelligent PDUs offer advanced monitoring and control, significantly boosting operational efficiency. Scalable designs future-proof investments. These strategic choices guarantee reliable and efficient power for critical IT infrastructure, supporting seamless data center operations.

FAQ

What are the primary socket types used in the UK, Germany, and France?

The UK uses BS 1363 (Type G) sockets. Germany primarily uses Schuko (CEE 7/3 and CEE 7/4) sockets. France utilizes Type E (CEE 7/5) sockets. Each country has distinct physical plug and socket designs.

What is the standard voltage for rack PDUs in the UK, Germany, and France?

The standard voltage requirement for rack PDUs in these European countries is typically 250VAC. Data centers commonly use 230V power for servers and networking equipment. This voltage aligns with broader European electrical standards.

Why are certifications like CE, UKCA, VDE, and NF important for European PDUs?

Certifications ensure product safety, quality, and compliance with local regulations. The CE mark is essential for EU market access. UKCA is for Great Britain. VDE signifies German electrical safety. NF indicates compliance with French standards. These marks guarantee reliable and safe operation.

How do intelligent PDUs differ from basic PDUs?

Intelligent PDUs offer advanced features. They provide real-time power monitoring, remote management, and environmental sensing. Basic PDUs only distribute power without these advanced capabilities. Intelligent PDUs enhance efficiency, reliability, and control in data centers.

What are the advantages of using vertical PDU placement in a rack?

Vertical PDUs, or 0U PDUs, mount along the sides of a rack. This placement saves valuable rack unit space for IT equipment. They also support higher outlet densities and improve airflow. This optimizes space and cooling in high-density environments.

Why is load balancing crucial for three-phase PDUs?

Load balancing distributes power evenly across all three phases. This prevents inefficiencies, overheating, and circuit breaker trips. Balanced loads optimize PDU performance and extend equipment lifespan. It ensures stable power delivery and prevents downtime.

How can organizations future-proof their European rack PDU investment?

Organizations can future-proof investments by choosing modular PDU designs. They should also plan for higher power capacities. Selecting intelligent PDUs with advanced features and ensuring DCIM integration supports scalability. This prepares infrastructure for evolving technology demands and growth.

Post time: Nov-10-2025